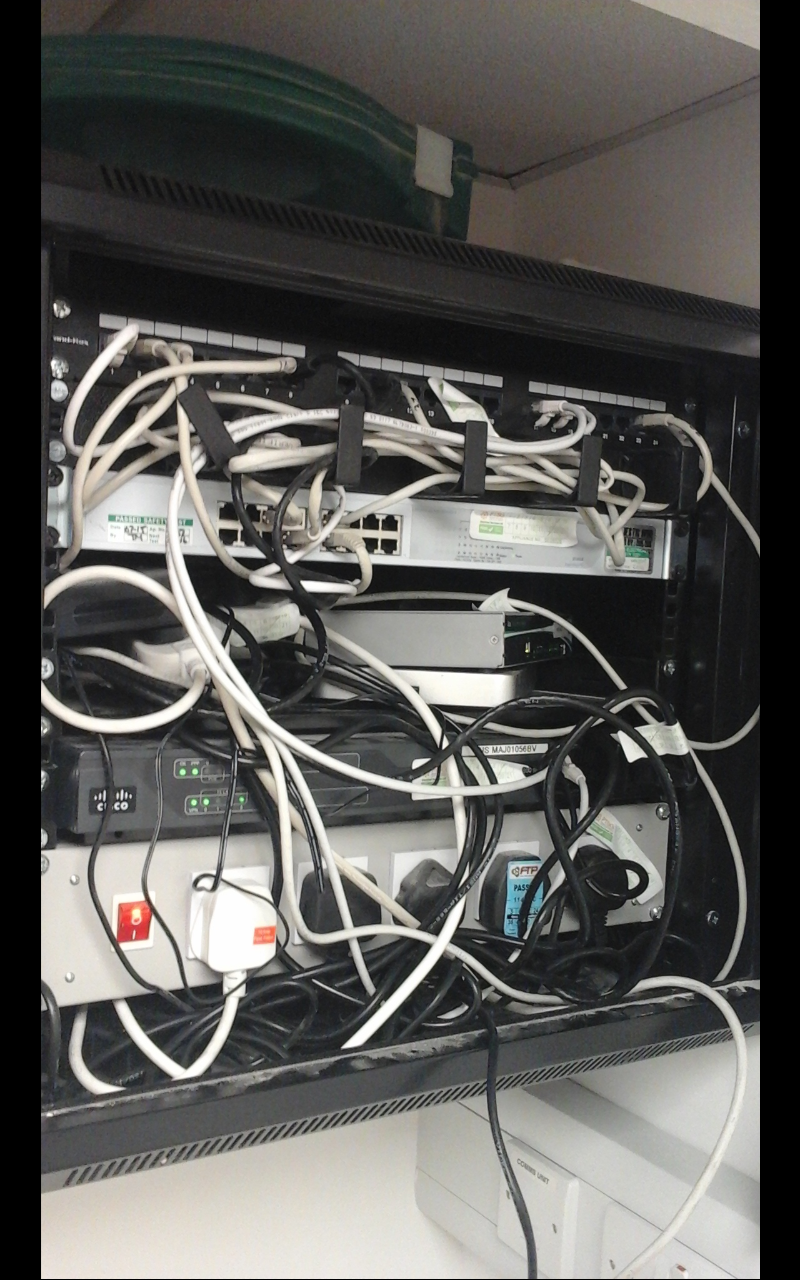

That's untidy ? I can tell you that compared to the majority of similar installations that's amazingly tidy

Though I see they've got the usual "lets provide some totally inadequate but ticks a box" power distribution panel in

Bit in response to your queries ...

Yes, each socket on the wall

should go to one of the numbered sockets in the patch panel. Each of those connections

should be wired correctly and have been tested on installation - but some installers CBA with minor details like making sure they've not got any bad connections (there's 16 connections per wall socket - 8 at the socket end, 8 at the patch panel end)

Similarly, some installers CBA labelling the sockets

In principle, you can move any connection to wherever there's a convenient wall socket and just move the corresponding patch lead at the cabinet. If you aren't 100% confident that everything's been done right, it would do no harm to do a quick test (your "box with 8 lights" tester will do) and see that at least all 8 lines are connected properly.

That's the point of "structured cabling" - you just have a load of identically wired sockets which you patch into whatever services are needed for any particular point. A couple of jobs ago I managed the internal systems which ran phone (analogue, digital (proprietary), ISDN), serial data (RS232), ethernet, and even the 10Mbps inter-system links used by the Transputers driving a serial I/O system. I had all the patch cables colour coded (blue for serial, green for phone, yellow for ethernet, and red for "don't touch this !") - after I left, someone thought it would be a bright idea to replace them all with black

Some of the jobs I've done in the past have been sorting out "problems" with poor installs - or "accidental" uninstalls.

In one case, someone had just cut all the cables and taken the patch panels out when moving out - it had been agreed between them, the landlord, and the next tenant that they'd leave the data cabling in place. I got the job of toning out about 60 sockets worth of unlabelled cables and re terminating them onto new panels. Apparently it had been a case of misunderstood instructions when someone was told to remove the cabinet

In another case, I was asked to test the data cabling in a small office. In this case, a tenant had been renting several offices but had moved out into a bigger space. They'd split the cabling which originally all went to one cabinet - but got it "wrong" big time. Clearly whoever did it never even tried testing anything or they'd have realised what they'd done - they'd read the labelling wrong on the back of the patch panel, so each incoming cable had 2 pairs on one socket and 2 pairs on the adjacent one. So for example, socket one was split between 1 & 2 on the patch panel, with socket 2 similarly split between 1&2. It took me a while to figure out exactly what they'd done, and what went where - not helped by random miswiring so I couldn't just assume the cables were 1, 2, 3, 4, ...

Same site as the last one, it was a science park where we had 2 sockets in each unit and a fibre network linking a load of switches - so with a few taps on a keyboard it was possible to provide internet access with little delay or need for a site visit. A tenant had recently moved out and cleaned out their old cabling to return the unit to standard spec - only they'd chopped off our cables as well. Luckily I was asked to check when I was onsite for something else, and managed to identify our cables (two cables in a hacked off bunch that were a slightly different shade of grey) and stick a socket on them - dangling from the ceiling which was as far as the cables reached.

On new installs, it's not uncommon for sparkies to install the cabling while they're pulling all the other stuff in. That can be fun

Some see no point in labelling the cables - or at least not in a legible manner. Some don't see the point of proving enough length to actually reach the terminations. Some can't see the point of even trying to make it look like they've tried to install what was on the diagram provided. On other jobs the sparkies put the containment in (eg dado trunking) but don't consider minor details like allowing you to use a compartment that's big enough for the cables that need to go in - and don't get me started on the sparky who genuinely believed that the divider only insulates one way so not the mains can't go in the smaller compartment