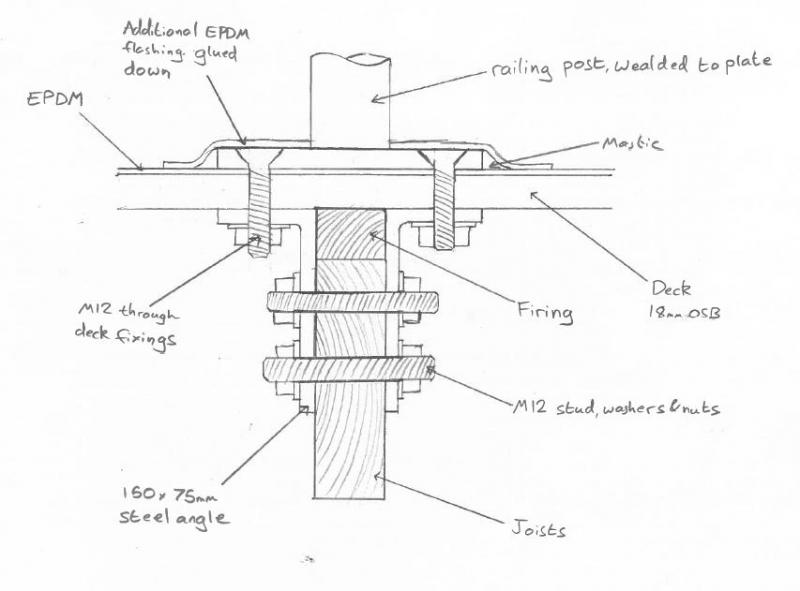

I am trying to work out the best way to fit hand rails that actually comply to building regs strength requirements THROUGH the deck of a new, EPDM covered flat roof. I am currently at this design, the calcs show that the steel comonents won't fail under test loads.

Can anyone offer a sanity check on the design?

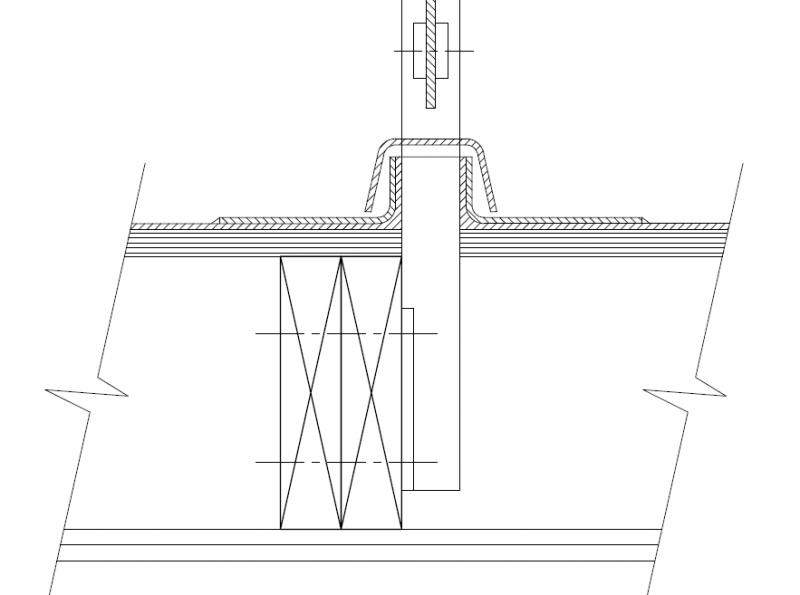

(Drawing not to scale)

Joists are 220x47 (3.8m span).

The post will be 50x50x3 box section steel welded to a 6mm thick plate. The studs (shown as countersunk screws) will be welded into place and ground so the top of the plate is smooth.

There will be 4 studs through the deck for each plate. And 3 studs going through the joists between the angles.

The plate will be welded to match the fall of the roof so that the posts are vertical when bolted down.

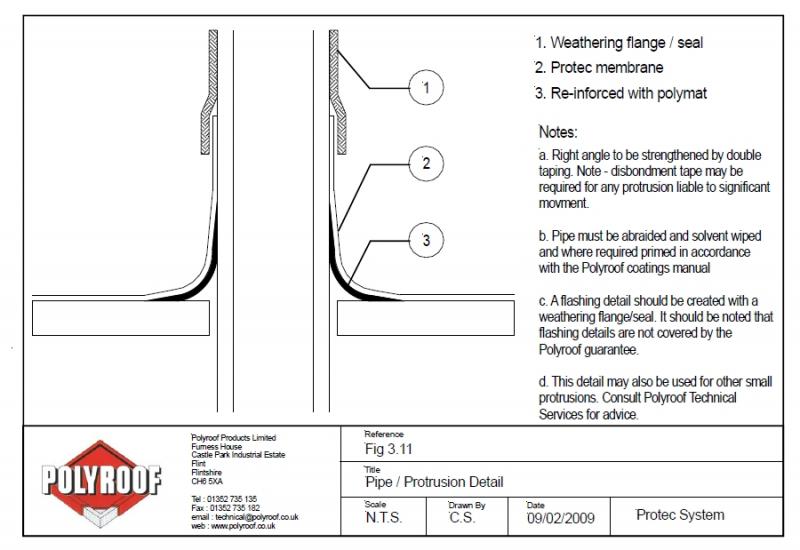

Silicone (or other sealant) will be used between the plate and the EPDM deck cover, a second piece of EPDM will be bonded over the plate to provide additional waterproofing.

Nylock nuts or shakeproof washers will be used to prevent nuts vibrating loose from foot traffic.

Along the sides of the roof, this arrangment will be attached to noggins rather than the joist to maintain load charactaristics.

All input welcome.

Cheers,

Fubar.

Can anyone offer a sanity check on the design?

(Drawing not to scale)

Joists are 220x47 (3.8m span).

The post will be 50x50x3 box section steel welded to a 6mm thick plate. The studs (shown as countersunk screws) will be welded into place and ground so the top of the plate is smooth.

There will be 4 studs through the deck for each plate. And 3 studs going through the joists between the angles.

The plate will be welded to match the fall of the roof so that the posts are vertical when bolted down.

Silicone (or other sealant) will be used between the plate and the EPDM deck cover, a second piece of EPDM will be bonded over the plate to provide additional waterproofing.

Nylock nuts or shakeproof washers will be used to prevent nuts vibrating loose from foot traffic.

Along the sides of the roof, this arrangment will be attached to noggins rather than the joist to maintain load charactaristics.

All input welcome.

Cheers,

Fubar.