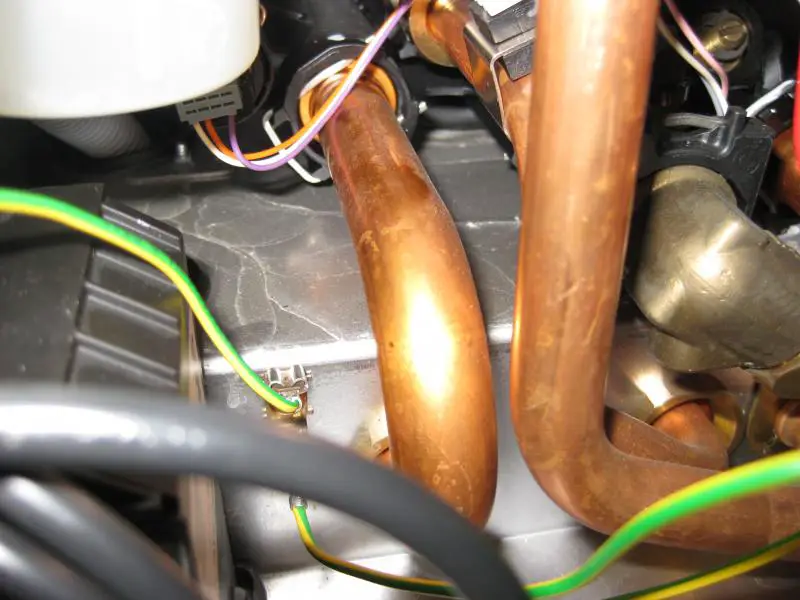

you might just get a new valve in if you undo the compression nut near the floor. you will need a certain amount of 'play' to get it in.

could be easier to spin the valve so it faces you. strip the gubbins out of it and make good all seals etc and reassemble.

B&Q will not be the cheapest place for a 22mm gate valve over the weekend.

most gate valves are compression, you might get away with re using the nuts and olives left on the pipe when you remove the old one. put some ptfe round the olives before you fit the new valve (not the thread)

if the nuts dont go onto the new valve easy enough do not force them, hacksaw carefully thru the old olives (without cutting the pipe) and prise off. then fit the new stuff.

could be easier to spin the valve so it faces you. strip the gubbins out of it and make good all seals etc and reassemble.

B&Q will not be the cheapest place for a 22mm gate valve over the weekend.

most gate valves are compression, you might get away with re using the nuts and olives left on the pipe when you remove the old one. put some ptfe round the olives before you fit the new valve (not the thread)

if the nuts dont go onto the new valve easy enough do not force them, hacksaw carefully thru the old olives (without cutting the pipe) and prise off. then fit the new stuff.