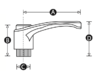

I have an M10 threaded rod 90mm length and I want to screw it into a clamping lever. How do I do this without damaging the threads on the rod and ensure it is as tight as possible? The lever will receive a lot of force in both directions during use so the rod needs to be rock solid. Hope someone can help. Cheers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How do you install a threaded rod into a clamping lever?

- Thread starter bennyboy1

- Start date

Sponsored Links

is the lever intended to pull the studding up a short way? And the studding screws in and out of it? You wind it round, like a car window winder? It looks closed at the top, so the studding can't project through.

If the winding handle is only 83mm long, you won't get a lot of force on it with your hand.

If the winding handle is only 83mm long, you won't get a lot of force on it with your hand.

Last edited:

Sponsored Links

Put 2 M10 nuts on the threaded rod, (sometimes called stud iron), slightly further back from the length of thread you want to screw into the handle.

Lock the 2 nuts together using two 17mm spanners. Run the rod intp the handle as far as it will go by hand. Using one of the 17mm spanners turn the nut which is furthest away from the handle until either the rod is fully inserted or you have reached the desired length. Using the 2 spanners you then unlock the 2 nuts and run them off the rod by the opposite end.

If you want to lock the threaded rod into position in the handle you can remove one nut and use the remaining one to run down to the handle and lock it tight using the spanner. This will prevent the rod from coming loose and falling out.

Lock the 2 nuts together using two 17mm spanners. Run the rod intp the handle as far as it will go by hand. Using one of the 17mm spanners turn the nut which is furthest away from the handle until either the rod is fully inserted or you have reached the desired length. Using the 2 spanners you then unlock the 2 nuts and run them off the rod by the opposite end.

If you want to lock the threaded rod into position in the handle you can remove one nut and use the remaining one to run down to the handle and lock it tight using the spanner. This will prevent the rod from coming loose and falling out.

The studding stays fixed inside the lever, it won't move up and down inside the lever. The lever is there to give leverage to tighten the stud into a hole the stud is screwed into. Not sure what you mean about not getting a lot of force.is the lever intended to pull the studding up a short way? And the studding screws in and out of it? You wind it round, like a car window winder? It looks closed at the top, so the studding can't project through.

If the winding handle is only 83mm long, you won't get a lot of force on it with your hand.

Thanks. Sounds good. I do need the stud to be locked in, but I don't want a nut to hold it in. It needs to be screwed in as tight as possible without a nut showing underneath. The lever will receive a lot of force in both directions when in use, so needs to be tight enough that when it receives that force the stud doesn't start undoing.Put 2 M10 nuts on the threaded rod, (sometimes called stud iron), slightly further back from the length of thread you want to screw into the handle.

Lock the 2 nuts together using two 17mm spanners. Run the rod intp the handle as far as it will go by hand. Using one of the 17mm spanners turn the nut which is furthest away from the handle until either the rod is fully inserted or you have reached the desired length. Using the 2 spanners you then unlock the 2 nuts and run them off the rod by the opposite end.

If you want to lock the threaded rod into position in the handle you can remove one nut and use the remaining one to run down to the handle and lock it tight using the spanner. This will prevent the rod from coming loose and falling out.

Sorry not sure what you mean. The stud/lever will be screwed into an M10 hole.So how is the studding attached to the component that you want it to remain fixed in relation to? Is the component its attached to threaded?

Thanks. Sounds good. I do need the stud to be locked in, but I don't want a nut to hold it in. It needs to be screwed in as tight as possible without a nut showing underneath. The lever will receive a lot of force in both directions when in use, so needs to be tight enough that when it receives that force the stud doesn't start undoing.

You just screw the studding in and give it a nip when it bottoms out.

If it comes undone when you undo the lever put some locktite on the thread.

Female levers work fine on studding.

Obviously you need a big washer between the lever and whatever you are tightening down onto

- Joined

- 22 Jul 2016

- Messages

- 5,896

- Reaction score

- 1,085

- Country

Loctite on the thread in the handle.

Use the double nut method to turn the threaded rod into the handle

The idea of double nutting is that the nut closer to the handle acts as a stop to the one further away.

Once done, the nuts are turned in opposite direction to separate and they can be spun off.

Use the double nut method to turn the threaded rod into the handle

The idea of double nutting is that the nut closer to the handle acts as a stop to the one further away.

Once done, the nuts are turned in opposite direction to separate and they can be spun off.

Not sure what you mean by 'giving it a nip when it bottoms out'. And also what do you mean... 'If it comes undone when you undo the lever put some lock time on the thread'? Sorry I'm a total noob when it comes to this DIY talk lolYou just screw the studding in and give it a nip when it bottoms out.

If it comes undone when you undo the lever put some locktite on the thread.

Female levers work fine on studding.

Obviously you need a big washer between the lever and whatever you are tightening down onto

Cheers. So will the loctite be strong enough to not let the stud come loose?Loctite on the thread in the handle.

Use the double nut method to turn the threaded rod into the handle

The idea of double nutting is that the nut closer to the handle acts as a stop to the one further away.

Once done, the nuts are turned in opposite direction to separate and they can be spun off.

Sponsored Links

Similar threads

- Replies

- 0

- Views

- 522