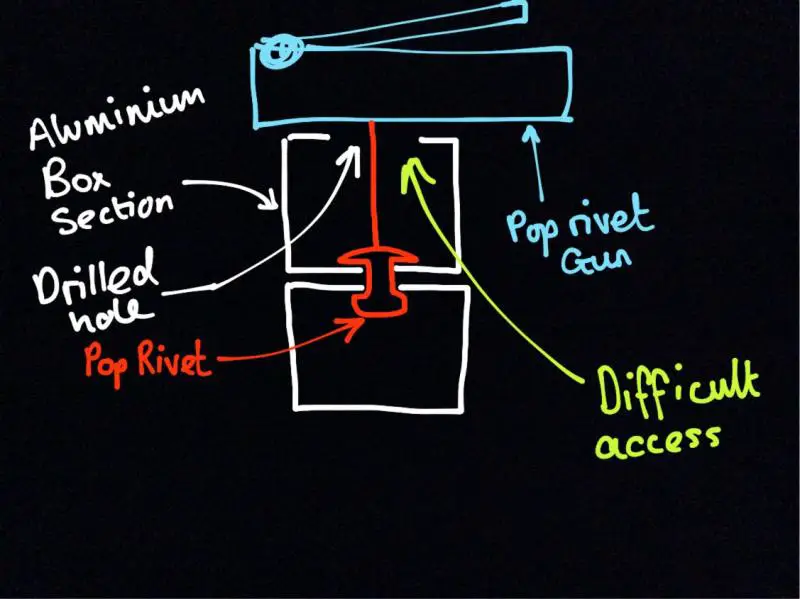

Hi, i'm going to need to attach two aluminium box sections together and I want to secure them mechanically with pop rivets. However, the problem is that becuase the box section is basically a tube, it will be difficult to use the rivet gun to put a rivet in the lower surface of the tube. Please see the attatched image for an explanation. As you can see, there is no way to get the rivet gun close enough to the rivet head to squeeze it. Does anyone know of a type of rivet or something similar which I could to do get around this problem?

Thanks!

Thanks!