It's not exactly a Herculean task to dig the filler out....It would have been handy of there were accessible screws to lift the front face of the wooden paneling off, but these have been filled in with wood filler.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mmmm how to run an outside cable from this consumer unit?

- Thread starter krieghammer

- Start date

Sponsored Links

H

holmslaw

..

At least bringing the cores and the sheath (that is between the cores and steel armour) in through the wall means the connections ( if any ) are inside the house and thus not prone to weather effects such as condensation of vapour from inside the house / cavity creating water in the external junction boxrather than taking the SWA on through - the latter approach may not work, because if you remove the sheath and armour from SWA what you are left with has to be kept in trunking or conduit, or enclosure(s) of some type.

True if the ducting is not necessary.Not installing the unneccesary ducting is a much better solution.

In an area where digging may occur in the future then ducting is a benefit that is almost 100% necessary. It it gives an extra inch or so of warning for the digger to be stopped before the sheath of the SWA is damaged. ( assuming there is a person watching the inch by inch excavation under the warning tape ).

And if the SWA is damaged then pulling a new length through the repaired duct is probably much better than having to make an underground joint from the digger mutilated ends of the SWA.

Or just wrap gaffer tape round the exposed steel and hope it doesn't corrode too quickly and interrupt the earth continuity.

Sponsored Links

What BS cable standard applies to the part of a SWA cable you are left with when you've removed the outer sheath and the armour?At least bringing the cores and the sheath (that is between the cores and steel armour) in through the wall ...

Mmmm tonnes of ideas flowing....

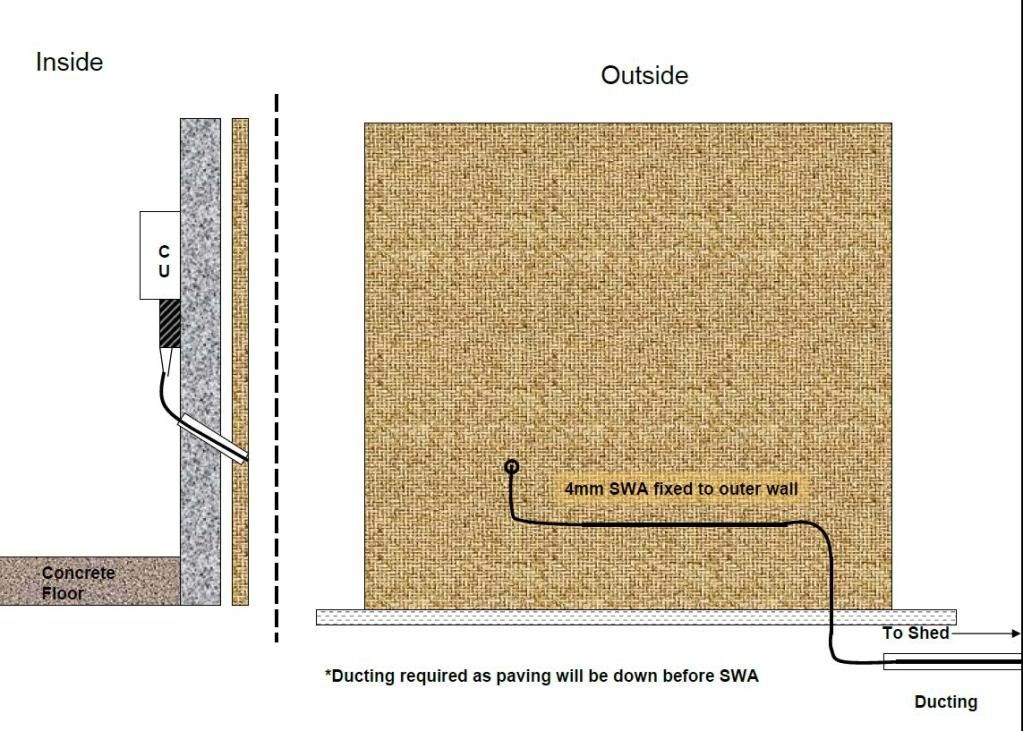

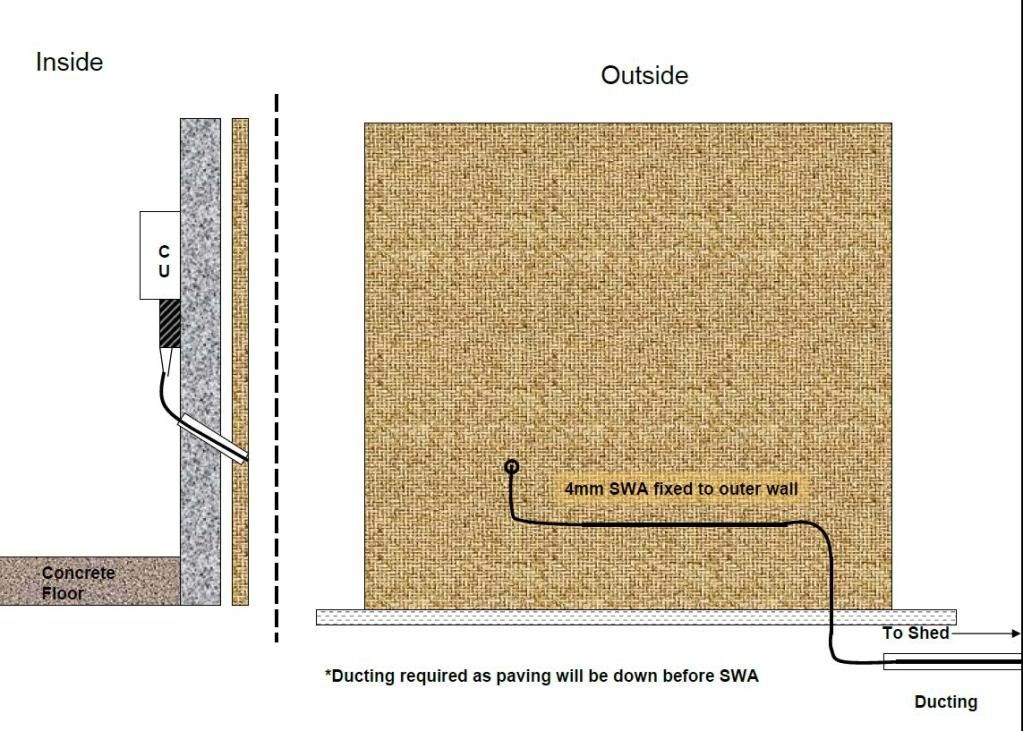

FP 200 cable from consumer unit (RCD protected).... Then through wall and terminate in external box. In external box, SWA cable. From there follow the wall of the house before turning down to the ground and into a duct (ducting needed as paving going down before power run to shed). SWA through ducting then terminated in shed. 2 way CU in shed to supply lights and a double socket.

FP 200 cable from consumer unit (RCD protected).... Then through wall and terminate in external box. In external box, SWA cable. From there follow the wall of the house before turning down to the ground and into a duct (ducting needed as paving going down before power run to shed). SWA through ducting then terminated in shed. 2 way CU in shed to supply lights and a double socket.

Am I missing something here? Why not just drill thru the wall at a steep down hill angle (viewed form inside)? No bending radii are going to be exceeded then.

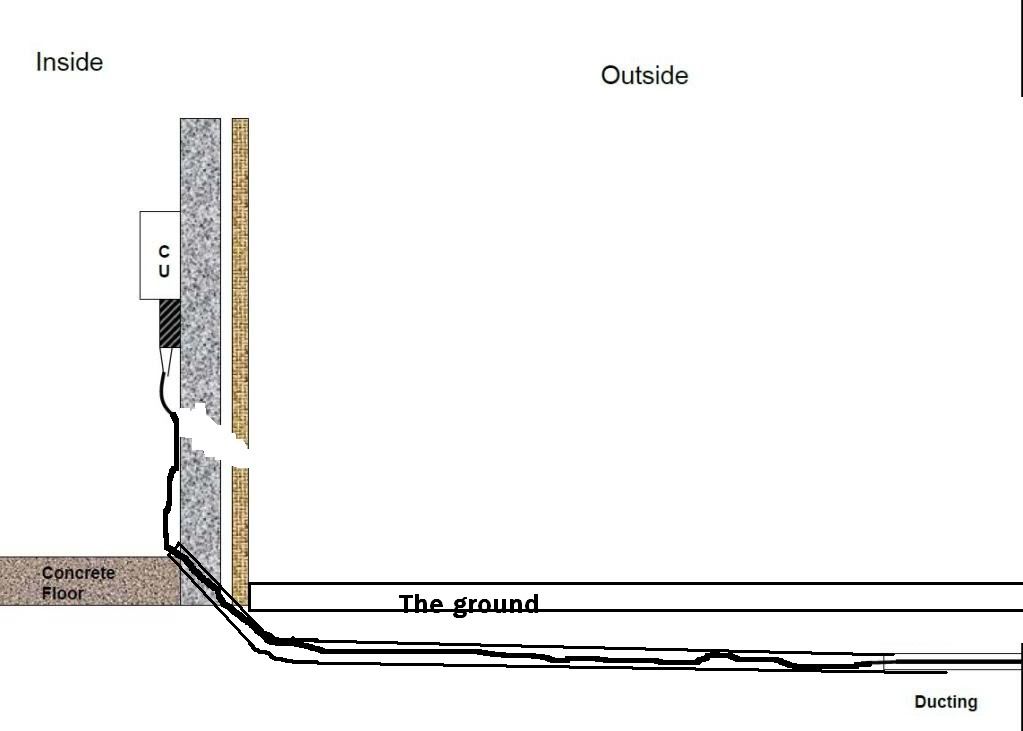

Ok drew a small plan here. In a nutshell this is what I envisage.

If you draw that looking from above, you still have a sharp bend in the SWA where it exits the hole in the wall and turns to run horizontally. Better to continue downwards from the exit hole and then you can put in a wider radius turn to run along the wall.

Sure that'd make more sense.

As suggested, ducting swept up inside a plastic pipe into an enclosure on the wall.

Will look much better than SWA cleated to the wall like that.

Will look much better than SWA cleated to the wall like that.

I see your point. Esp if a cleat fell off then the cable would just 'hang' off the wall. Plastic conduit for the SWA to run through will look better aesthetically I suppose. Thanks for the ideas and inputs so far. Just trying to think this through properly.

I see what you mean now. Just trying to avoid digging up the slabs and avoiding the waste pipe that runs parallel. I'd hate to drill through that!

Thought you were putting in the ducting before the slabs were put down?

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 19

- Views

- 5K