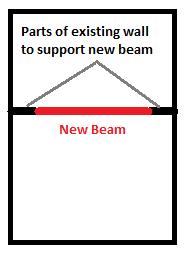

We will be taking out a load-bearing wall and installing a steel beam. We have a couple of questions:

1. Do we need to secure the beam into the pad stones, or will it's sheer weight be sufficient to prevent if from ever slipping off the wall?

2. How do we box the beam in? Is the usual process to fix timber studwork to the beam, if so, how do we attach this to the beam?

3. Do we rest the upstairs floor joists onto the steel beam, or lay a timber 'wall plate' on top of the steel beam for the floor joists to then screw into?

ps. Building Control will be involved for this job and we have had an engineer specify the size of beam.

1. Do we need to secure the beam into the pad stones, or will it's sheer weight be sufficient to prevent if from ever slipping off the wall?

2. How do we box the beam in? Is the usual process to fix timber studwork to the beam, if so, how do we attach this to the beam?

3. Do we rest the upstairs floor joists onto the steel beam, or lay a timber 'wall plate' on top of the steel beam for the floor joists to then screw into?

ps. Building Control will be involved for this job and we have had an engineer specify the size of beam.