Hi All

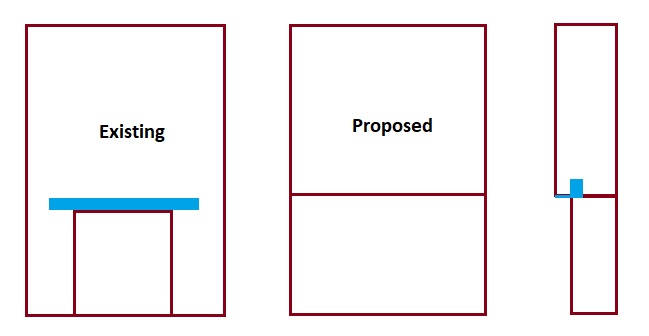

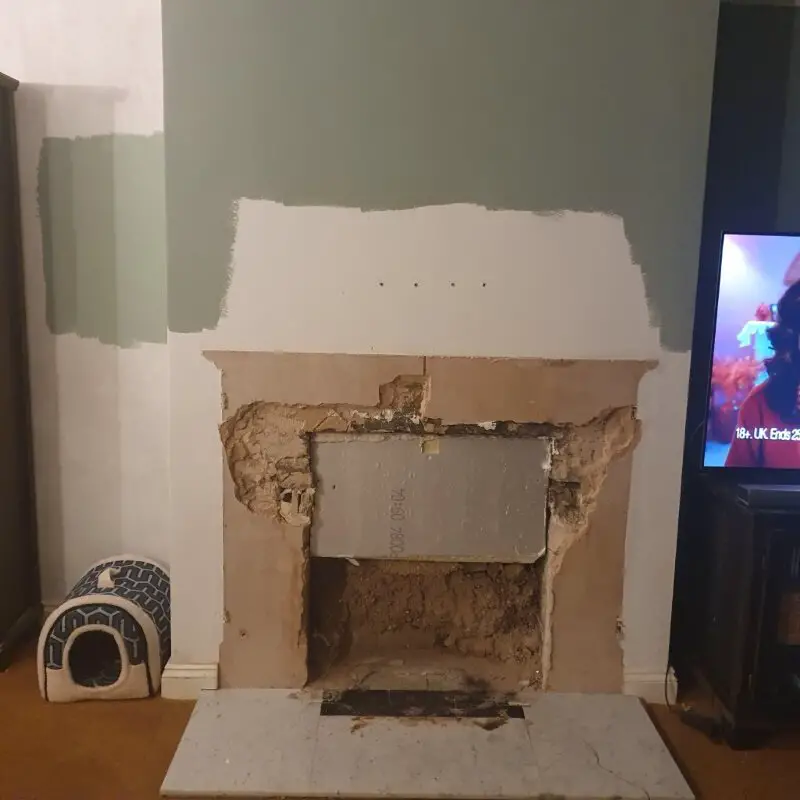

Our living room has an unused fireplace I want to form the basis of built in units to one side and a media wall for the TV on the existing chimney breast as it's the ideal place in the room for it, but we'd also like either a wide decorative fireplace or openings underneath the TV across the full width of the chimney breast where the old fireplace is. That leaves me with a problem to solve with the existing fireplace opening as the lintel is currently only about 2/3 of the width of the stack so doesn't give me the opening width I need.

We don't have the budget or dust tolerance to remove the chimney stack entirely across 2 floors and it's too big for gallows brackets so what I'd like to do is replace the existing lintel with a full width lintel/steel, ideally with front plate to support the front brick face to create about 10-15cm of overhang across the chimney stack. This would give me enough undercut to put the fireplace / alcoves underneath and build out the front face a little with studwork without the whole thing taking up too much extra room space.

Is what I'm proposing do-able (images below) or is there a better, more recognised way to achieve this? Whatever we do I'm guess it would need structural engineer calculations and BC notice would it?

cheers

Our living room has an unused fireplace I want to form the basis of built in units to one side and a media wall for the TV on the existing chimney breast as it's the ideal place in the room for it, but we'd also like either a wide decorative fireplace or openings underneath the TV across the full width of the chimney breast where the old fireplace is. That leaves me with a problem to solve with the existing fireplace opening as the lintel is currently only about 2/3 of the width of the stack so doesn't give me the opening width I need.

We don't have the budget or dust tolerance to remove the chimney stack entirely across 2 floors and it's too big for gallows brackets so what I'd like to do is replace the existing lintel with a full width lintel/steel, ideally with front plate to support the front brick face to create about 10-15cm of overhang across the chimney stack. This would give me enough undercut to put the fireplace / alcoves underneath and build out the front face a little with studwork without the whole thing taking up too much extra room space.

Is what I'm proposing do-able (images below) or is there a better, more recognised way to achieve this? Whatever we do I'm guess it would need structural engineer calculations and BC notice would it?

cheers