Hopefully someone can help with this.

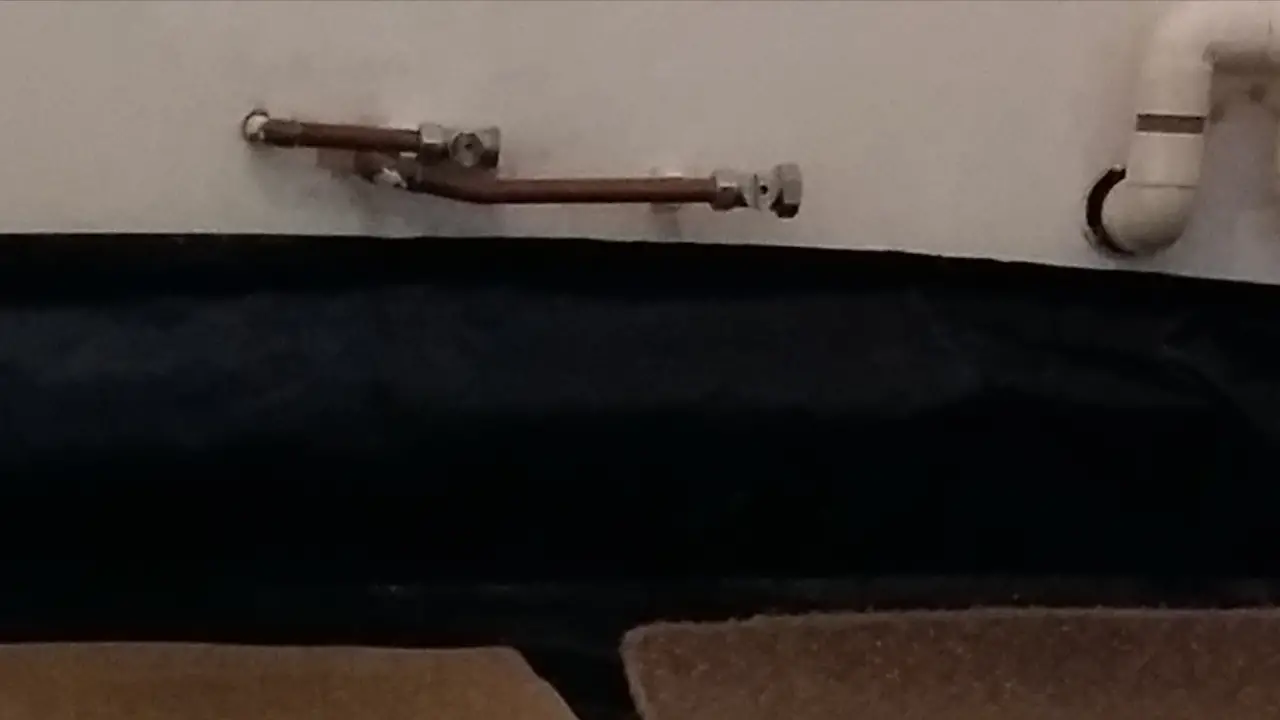

I have two water feeds in my garage that is being converted into a utility room. One hot and one cold feed. Previously used for washing machine so they both have appliance bsp valve connectors.

What is the easiest way to connect the washing machine and a sink tap to the cold feed and extend the hot to the tap.

I'm assuming the best way would be to chop out the existing connectors and put in a machine valve tee straight off the copper pipe? Then just extend the copper pipe on the hot direct to the tap with speed fit type connectors? I can't find any connectors to utilise the exitising bsp fittings. That was my first hope as they are well fitted and I assumed ready to just connect to.

Any ideas? Cheers, Lee

I have two water feeds in my garage that is being converted into a utility room. One hot and one cold feed. Previously used for washing machine so they both have appliance bsp valve connectors.

What is the easiest way to connect the washing machine and a sink tap to the cold feed and extend the hot to the tap.

I'm assuming the best way would be to chop out the existing connectors and put in a machine valve tee straight off the copper pipe? Then just extend the copper pipe on the hot direct to the tap with speed fit type connectors? I can't find any connectors to utilise the exitising bsp fittings. That was my first hope as they are well fitted and I assumed ready to just connect to.

Any ideas? Cheers, Lee