I have a "cold" flat roof in which we are taking the ceiling down, so want to use the opportunity to renew the very thin original fibre glass insulation.

The roof has just been resurfaced, so not an option to fit insulated boards on top.

We have fire rated lv downlighters, so my question is, what is the best insulation option?

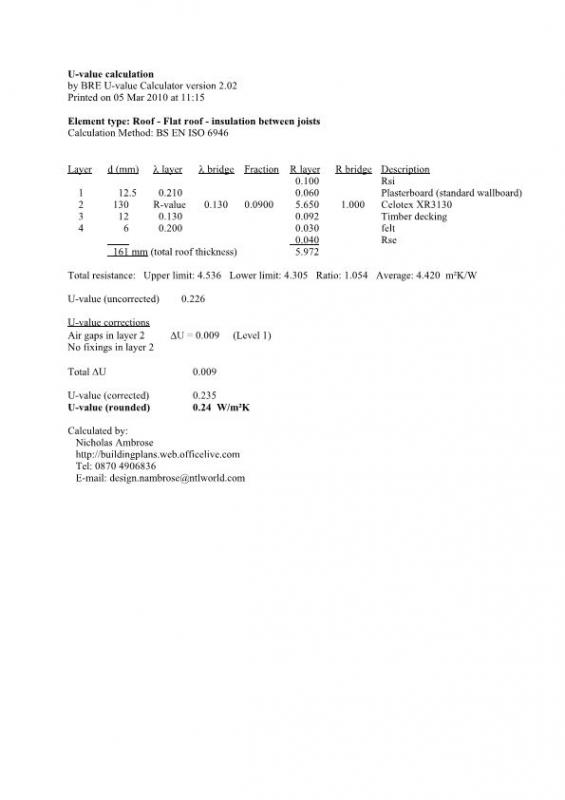

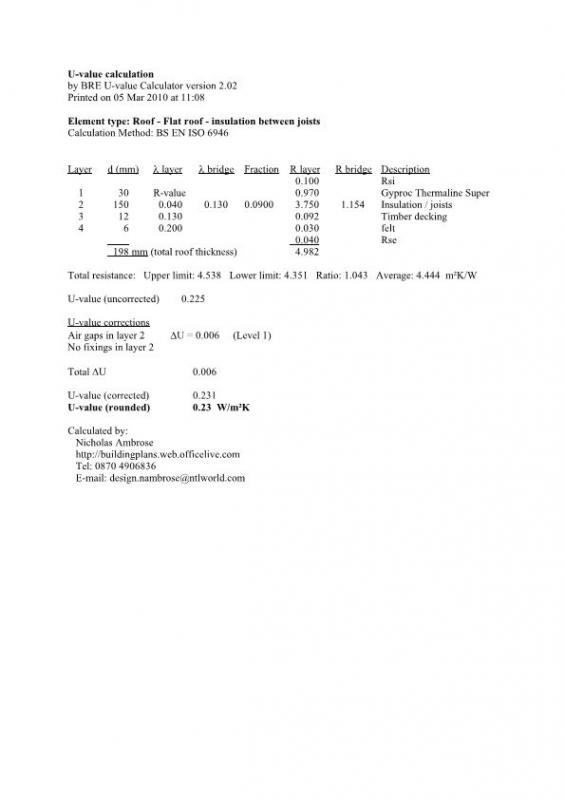

Joists are quite tall (200mm) so I had intended to fit 50 or 75mm celotex tight up to the underside of the roof boards between the joists, giving me a ventilation gap of 125 - 150mm between celotex and plasterboard, and a 25 - 50mm gap between celotex and top of downlighter.

BUT, should I actually have the vent gap above the celotex rather than below it?

I have had conflicting advice i.e:

1. That I need vent gap above celotex to prevent condensation on underside of boards.

2. That it is fine to fit celotex tight up to boards / joists, as then there shouldn't be any condensation.

If I lowered the celotex to provide a gap, it would interfere with the downlighters unless I start cutting holes in the vapour control layer which kind of defeats the object.

Or should I not bother with celotex and refill the gaps between the joists with a thicker layer of fibre glass type insulation, ensuring gaps round the downlighters and transformers where there would effectively be no insulation?

Sorry it's a long one, hope you can help.

Thanks.

The roof has just been resurfaced, so not an option to fit insulated boards on top.

We have fire rated lv downlighters, so my question is, what is the best insulation option?

Joists are quite tall (200mm) so I had intended to fit 50 or 75mm celotex tight up to the underside of the roof boards between the joists, giving me a ventilation gap of 125 - 150mm between celotex and plasterboard, and a 25 - 50mm gap between celotex and top of downlighter.

BUT, should I actually have the vent gap above the celotex rather than below it?

I have had conflicting advice i.e:

1. That I need vent gap above celotex to prevent condensation on underside of boards.

2. That it is fine to fit celotex tight up to boards / joists, as then there shouldn't be any condensation.

If I lowered the celotex to provide a gap, it would interfere with the downlighters unless I start cutting holes in the vapour control layer which kind of defeats the object.

Or should I not bother with celotex and refill the gaps between the joists with a thicker layer of fibre glass type insulation, ensuring gaps round the downlighters and transformers where there would effectively be no insulation?

Sorry it's a long one, hope you can help.

Thanks.