- Joined

- 7 Feb 2008

- Messages

- 206

- Reaction score

- 6

- Country

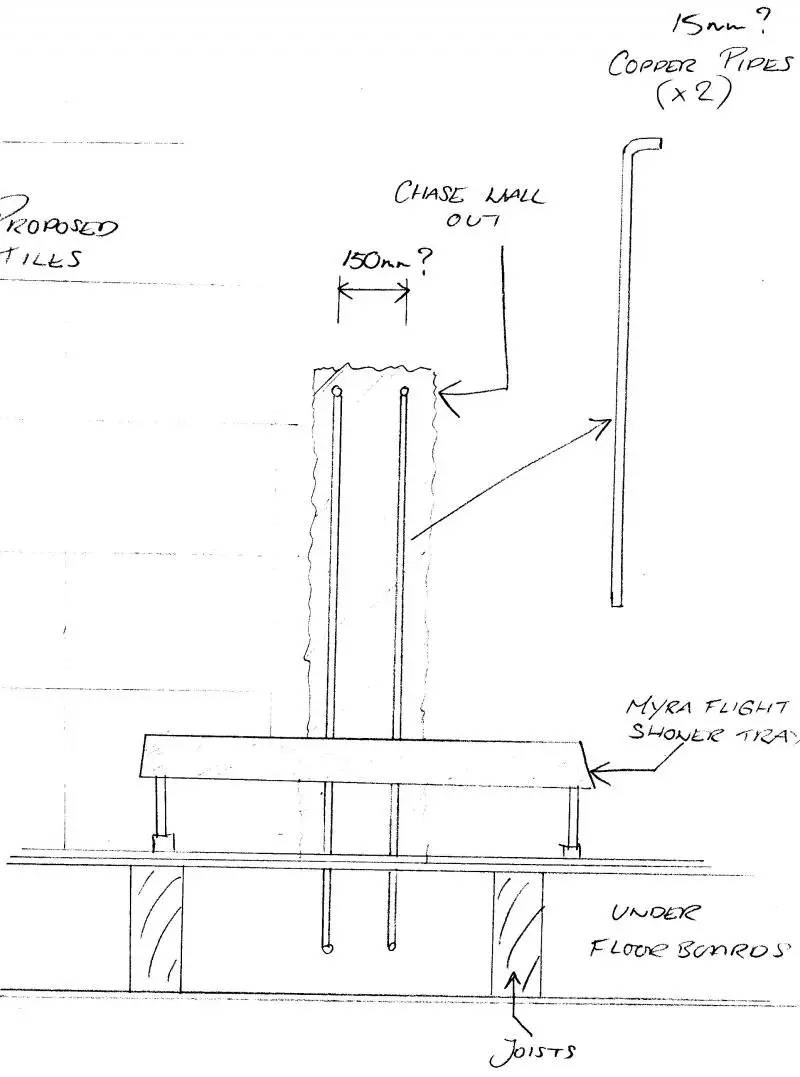

I would like to install a shower cubicle in my bathroom, I am not ready to get a plumber as yet.

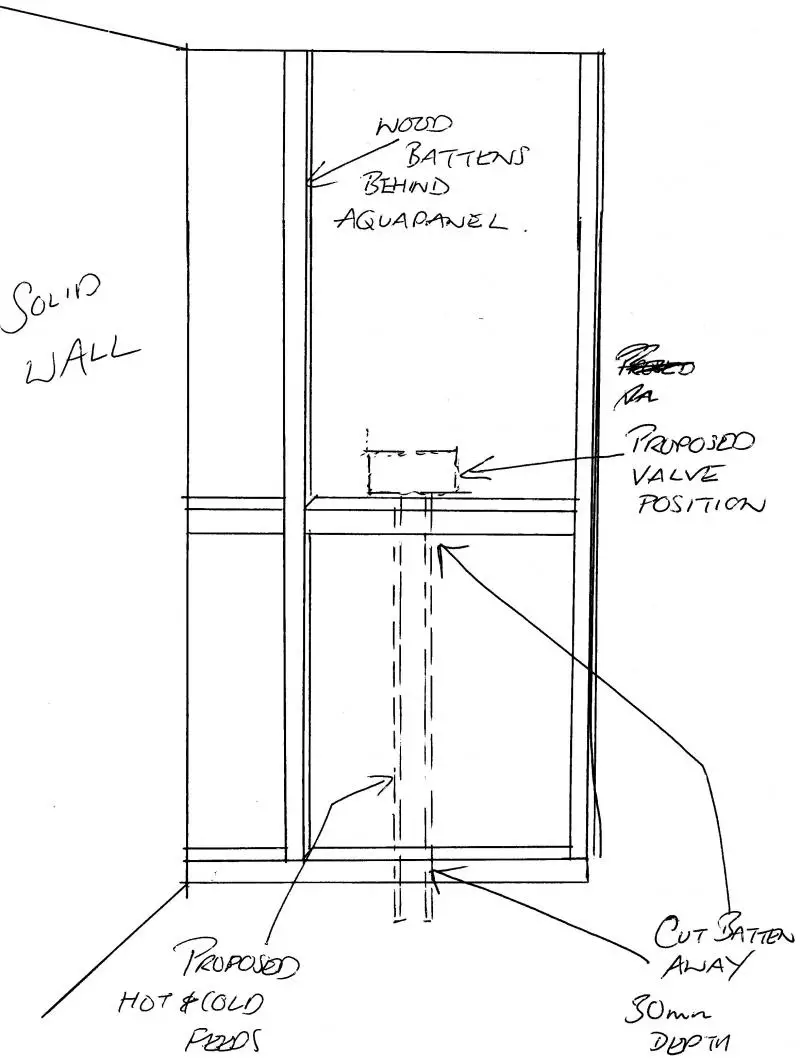

I was thinking of doing some of the prep work; i.e. place the shower tray in position and tile the walls. Before I can tile the walls I must make sure the hot and cold feeds are buried in the walls ready for the new shower taps.

I would like to 'chase' the wall out and place 2 x copper pipes in the wall ready for the hot and cold taps (please see the diagram), the bottom of the pipes would be under the floor ready for a plumber to connect to a nearby hot and cold (this is running off a combi boiler).

1/. I believe the copper pipes should be 15mm?

2/. Should they be 150mm apart (ready for the shower taps to screw on)?

3/. How deep should the pipes be in the wall?

4/. I know I can't buy these copper pipes 'off the shelf' should I contact a local plumber and have them made, or is there another way to get around the problem (place some sort of duct in the wall)?

I know this isn't the best way about going about things, but will it be okay to do it? I have some spare time on my hands at the moment - but not a lot of cash.

Any input would be greatly appreciated.

Thanks.

I was thinking of doing some of the prep work; i.e. place the shower tray in position and tile the walls. Before I can tile the walls I must make sure the hot and cold feeds are buried in the walls ready for the new shower taps.

I would like to 'chase' the wall out and place 2 x copper pipes in the wall ready for the hot and cold taps (please see the diagram), the bottom of the pipes would be under the floor ready for a plumber to connect to a nearby hot and cold (this is running off a combi boiler).

1/. I believe the copper pipes should be 15mm?

2/. Should they be 150mm apart (ready for the shower taps to screw on)?

3/. How deep should the pipes be in the wall?

4/. I know I can't buy these copper pipes 'off the shelf' should I contact a local plumber and have them made, or is there another way to get around the problem (place some sort of duct in the wall)?

I know this isn't the best way about going about things, but will it be okay to do it? I have some spare time on my hands at the moment - but not a lot of cash.

Any input would be greatly appreciated.

Thanks.