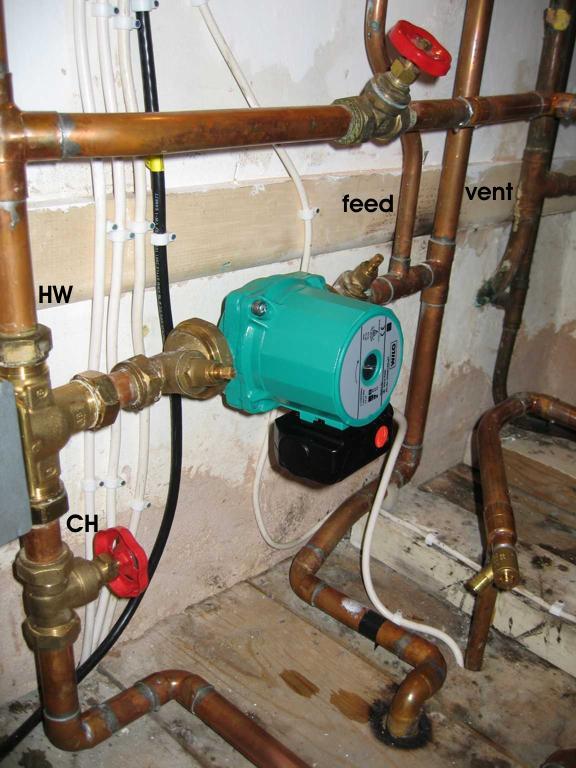

I have just had some problems with my system fixed - and now I have different problems. When I bleed my radiators, they soon get air pockets in again. The fill pipe from my F&E tank also gets hot, so I think hot water is blowing back up it. When I bleed a radiator and go back to the fill, it is cool again.

I am confused for several reasons. How does air get into the system? Why does water expand up the fill pipe and not the expansion pipe? Should there be a NRV on the fill pipe at the tank?

I am confused for several reasons. How does air get into the system? Why does water expand up the fill pipe and not the expansion pipe? Should there be a NRV on the fill pipe at the tank?