I have had this issue for years, and even replacing the three port valve completely did not solve it. Now with the gas prices so high I would like to get to the bottom of the issue.

Could it be some sort of convection causing a reverse flow into certain radiators. I notice that about half the radiators get hot.

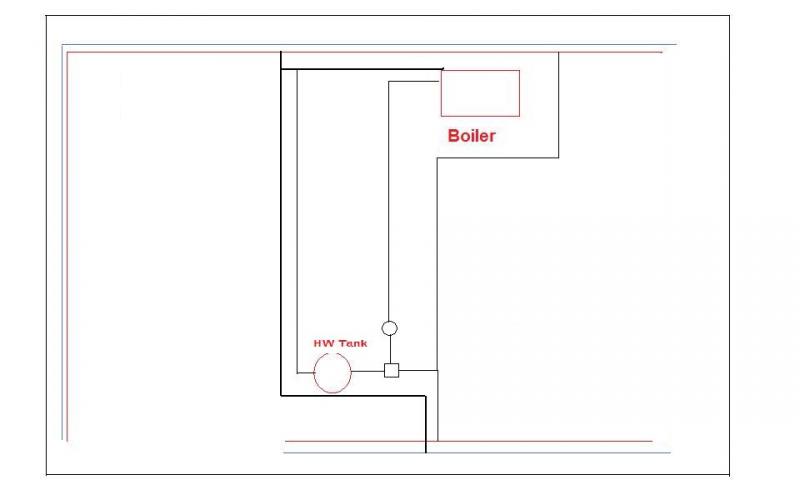

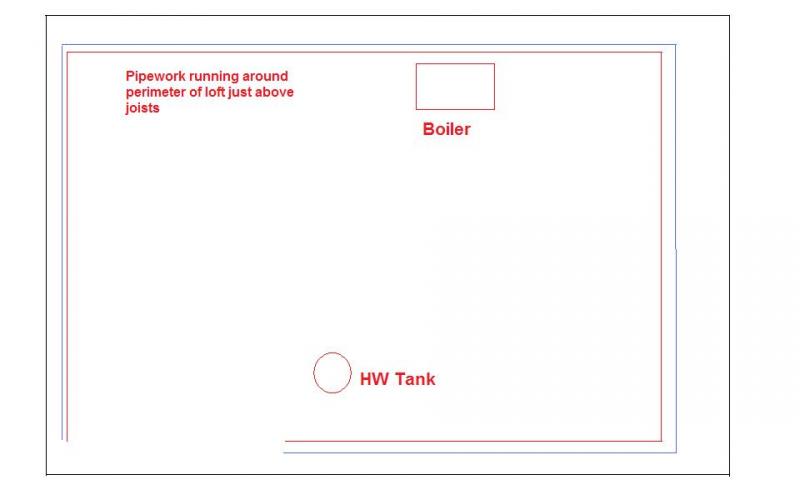

I have a bungalow with all the CH pipes running in the loft, and the individual pipes to radiators drop through the ceiling adjacent to each rad.

All of the rads are equipped with thermostatic valves, but in addition I have a Potterton programmer with temperature set back, so the radiators where the stat is located have either had the thermostatic element removed or fully opened.

I would be grateful for any suggestions as how to (a) find out what is happening to cause them to heat up, and (b) how to remedy the situation.

One idea I had was to find the flow pipes after the "Y" piece and insert solenoid valves here wired to the appropiate contacts on the programmer so that both flow AND return are closed off when the relevant thermostat closes. Surely this would eliminate the issue, however could it cause pressure build up leading to other problems?

Thanks Chris

Could it be some sort of convection causing a reverse flow into certain radiators. I notice that about half the radiators get hot.

I have a bungalow with all the CH pipes running in the loft, and the individual pipes to radiators drop through the ceiling adjacent to each rad.

All of the rads are equipped with thermostatic valves, but in addition I have a Potterton programmer with temperature set back, so the radiators where the stat is located have either had the thermostatic element removed or fully opened.

I would be grateful for any suggestions as how to (a) find out what is happening to cause them to heat up, and (b) how to remedy the situation.

One idea I had was to find the flow pipes after the "Y" piece and insert solenoid valves here wired to the appropiate contacts on the programmer so that both flow AND return are closed off when the relevant thermostat closes. Surely this would eliminate the issue, however could it cause pressure build up leading to other problems?

Thanks Chris