(Not sure if this should be here or in Woodworking....)

Situation- garage shell is up. Wallplates are on (machined with a 10 degree slope because the rafters are JJ I beams so can't be birdmouthed- manufacturer would rather have sold me some tarty clamps but agreed that sloping wallplate and skew nailing were completely acceptable. BCO also happy with the scheme). The high wall is currently 3915 above DPC, low wall is 2700 above DPC- once the joists, battens and roof sheets are on that'll take top height to about 4420 which keeps me inside the PP.

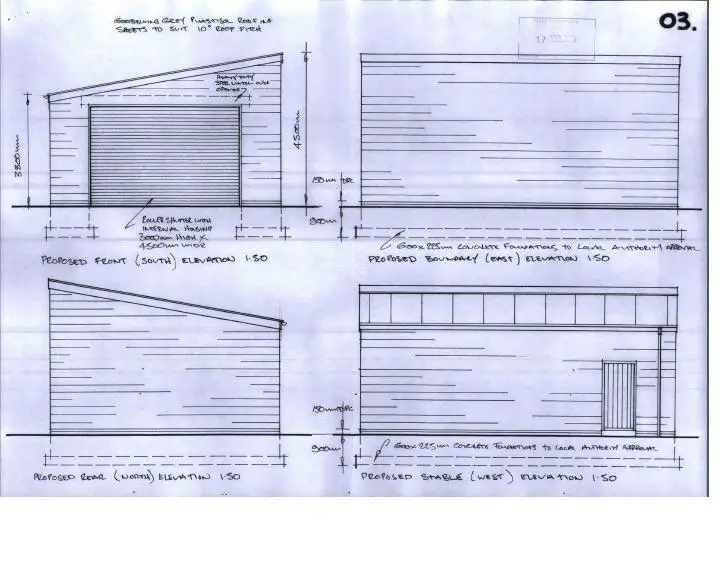

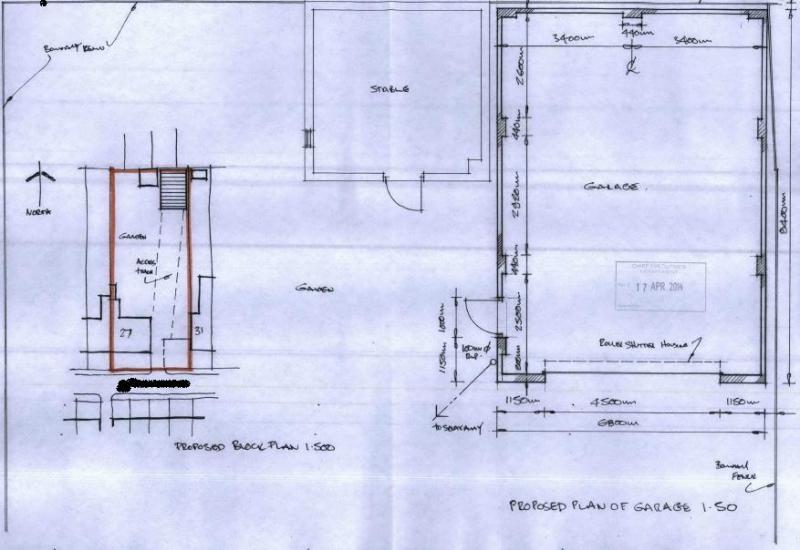

Plans

Sample rafter

Issues- While marking out the spacings for the rafters I found that the high wall is 30mm longer than the low wall and the door gable end is about 20mm longer than the other gable end. And the diagonals don't quite match (which is irritating because they did at ground level). There is also about 10mm of runout on the high wall and about 5mm on the low wall- nothing to worry about structurally but here come the questions;

Questions-

1 Will the bargeboard look like a dogs' hind leg if I just measure all the rafter lengths (by tape from outside edge of wallplate to outside edge of wallplate), add 10mm each end for badness/overhang and trim them to vertical (so the rafter ends and thus the bargeboard will follow the runout on the walls) or will I be better off setting a line outside each wall and measuring/marking the rafters to that (prefer measure- they're 35 kg apiece so really don't fancy lifting them up, marking, dropping, cutting and lifting again)?

2 Roof covering is going to be corrugated GRP sheets (not sure what profile yet, hopefully Big 6 since I can use any spare to overclad the stable). Anyway, am I right in thinking that there'll be enough flex in the stuff for me to lose the 30mm difference across 10 metres (by pushing the bottom overlaps tight and letting the top overlaps go a bit loose). I've done that trick with polycarbonate sheets but GRP is a new one for me.

3 Bargeboards- they need to be massive (350mm minimum, ideally 400mm) to cover the joist ends, wallplate, battens etc. Any thoughts on what would be best to use given that they're going to be nigh-on impossible to access for any maintenance once the roofing sheets are on- I'm thinking uPVC hollow soffit boards at the top (because they're moderately cheap) and uPVC bargeboards at the bottom (need something chunky to fit the guttering to) but any other suggestions gratefully received.

If there are any beartraps that I need to look out for on this job please let me know- this is the first time I've played with these JJ I beams and at about £60 each I don't really want to cock the job up. First roof I'll have done from scratch as well........

Situation- garage shell is up. Wallplates are on (machined with a 10 degree slope because the rafters are JJ I beams so can't be birdmouthed- manufacturer would rather have sold me some tarty clamps but agreed that sloping wallplate and skew nailing were completely acceptable. BCO also happy with the scheme). The high wall is currently 3915 above DPC, low wall is 2700 above DPC- once the joists, battens and roof sheets are on that'll take top height to about 4420 which keeps me inside the PP.

Plans

Sample rafter

Issues- While marking out the spacings for the rafters I found that the high wall is 30mm longer than the low wall and the door gable end is about 20mm longer than the other gable end. And the diagonals don't quite match (which is irritating because they did at ground level). There is also about 10mm of runout on the high wall and about 5mm on the low wall- nothing to worry about structurally but here come the questions;

Questions-

1 Will the bargeboard look like a dogs' hind leg if I just measure all the rafter lengths (by tape from outside edge of wallplate to outside edge of wallplate), add 10mm each end for badness/overhang and trim them to vertical (so the rafter ends and thus the bargeboard will follow the runout on the walls) or will I be better off setting a line outside each wall and measuring/marking the rafters to that (prefer measure- they're 35 kg apiece so really don't fancy lifting them up, marking, dropping, cutting and lifting again)?

2 Roof covering is going to be corrugated GRP sheets (not sure what profile yet, hopefully Big 6 since I can use any spare to overclad the stable). Anyway, am I right in thinking that there'll be enough flex in the stuff for me to lose the 30mm difference across 10 metres (by pushing the bottom overlaps tight and letting the top overlaps go a bit loose). I've done that trick with polycarbonate sheets but GRP is a new one for me.

3 Bargeboards- they need to be massive (350mm minimum, ideally 400mm) to cover the joist ends, wallplate, battens etc. Any thoughts on what would be best to use given that they're going to be nigh-on impossible to access for any maintenance once the roofing sheets are on- I'm thinking uPVC hollow soffit boards at the top (because they're moderately cheap) and uPVC bargeboards at the bottom (need something chunky to fit the guttering to) but any other suggestions gratefully received.

If there are any beartraps that I need to look out for on this job please let me know- this is the first time I've played with these JJ I beams and at about £60 each I don't really want to cock the job up. First roof I'll have done from scratch as well........