Hi

After my previous post regarding the length of the universal beam I require getting sorted (turned out dead simple) I have now ordered them and they are coming within a few days. I want to get everything ready for when they arrive so I can crack on over the weekend, I have a few questions I'm hoping you can help with.

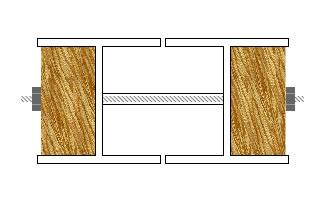

The wall I'm taking out is a cavity wall which is in good condition so will be using this as the support. Here's a few pictures and dimensions to get things moving:

Left wall - 940mm

Right wall - 1170mm

Sliding Doors - 2400mm

First question is how many steel props will I need internally? And is it acceptable to use two scaffolding boards to spread the load across the props? Similar question, how many strongboy props will I need on the external wall?

The load on each wall (internal block and external brick) is 45.81kN according to the calculations done by the structural engineer.

From my reading some people prefer to put the padstones in first and then UBs in after, some the other way around by supporting the UB and then padstones up against it. If there is such a thing, which is the best way or most recommended way?

Do the UBs simply sit on the padstones or should they be on a bed of mortar?

I think I'm asking the impossible here but may aswell ask. Instead of having the 1st floor joists sitting on top of the internal UB is it possible or allowed to have the joists sit inside the UB so that the ceiling can be one big run instead of split up by a box section.

I'll admit that I have never done this before but am not afraid to do the work. I'd rather ask loads of questions and be perfectly clear.

Many thanks for advice in advance.

After my previous post regarding the length of the universal beam I require getting sorted (turned out dead simple) I have now ordered them and they are coming within a few days. I want to get everything ready for when they arrive so I can crack on over the weekend, I have a few questions I'm hoping you can help with.

The wall I'm taking out is a cavity wall which is in good condition so will be using this as the support. Here's a few pictures and dimensions to get things moving:

Left wall - 940mm

Right wall - 1170mm

Sliding Doors - 2400mm

First question is how many steel props will I need internally? And is it acceptable to use two scaffolding boards to spread the load across the props? Similar question, how many strongboy props will I need on the external wall?

The load on each wall (internal block and external brick) is 45.81kN according to the calculations done by the structural engineer.

From my reading some people prefer to put the padstones in first and then UBs in after, some the other way around by supporting the UB and then padstones up against it. If there is such a thing, which is the best way or most recommended way?

Do the UBs simply sit on the padstones or should they be on a bed of mortar?

I think I'm asking the impossible here but may aswell ask. Instead of having the 1st floor joists sitting on top of the internal UB is it possible or allowed to have the joists sit inside the UB so that the ceiling can be one big run instead of split up by a box section.

I'll admit that I have never done this before but am not afraid to do the work. I'd rather ask loads of questions and be perfectly clear.

Many thanks for advice in advance.