*Assuming the pretty drawing is as fitted, I wouldn't expect it to work.

*Also I don't see this schematic on systemlinks website which shows the cold feed/vent arrangement connected on the gravity circuit

The pretty drawing was drawn by Systemlink

*the bottom coil should be used for the gravity, or the middle coil at a pinch

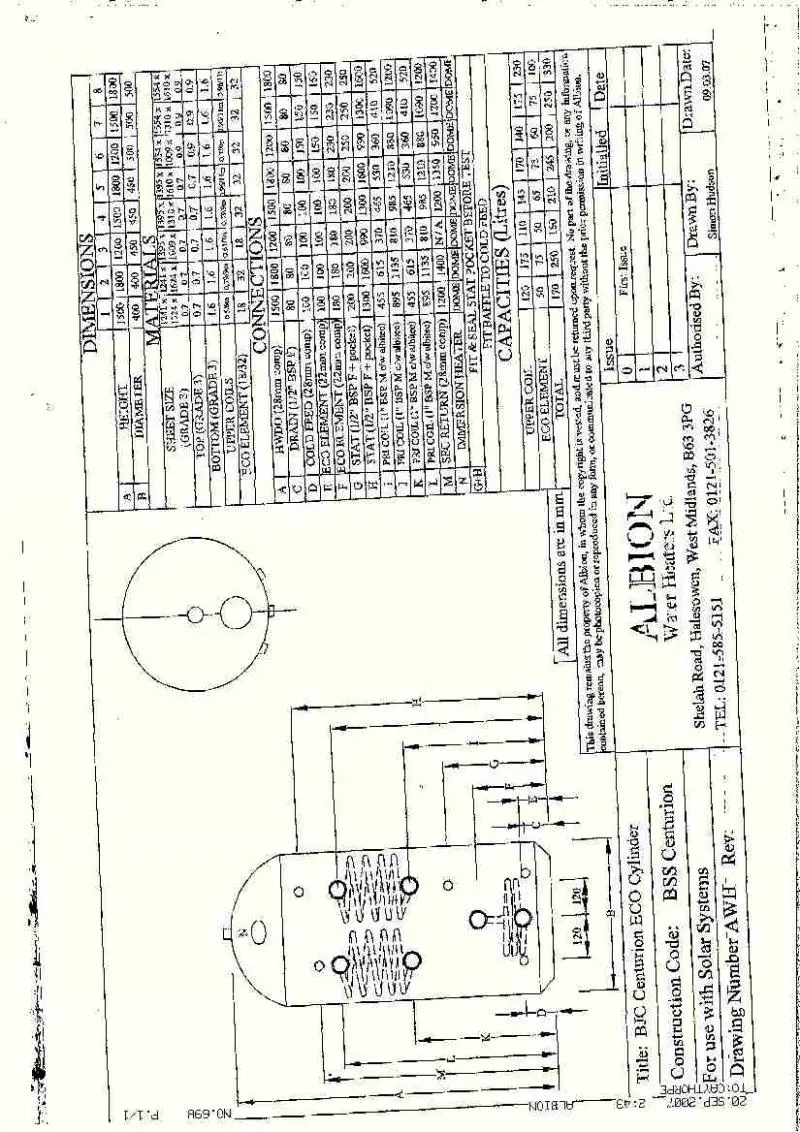

I should clarify that the top and middle coils are intertwined in the cylinder, not at different levels as shown by the drawing. Attached drawing, number 5 1800x450

*there's no provisions to vent the primary circuit of air.

The vent is on the primary circuit. The Systemzone box has an auto air vent.

* the cold feed and vent must be on the gravity circuit.

Good point. The water cannot expand to begin circulating.

*there should be cross flow across the boiler.

There is cross flow. This drawing omits that detail.

*I'm surprised no one has questioned the cold feed which is impeded with valves and a circulator!

Nope - gravity circuit has no valves, circulators, pumps or anything on it. As shown in the pretty drawing.