Hi.

My builder has last week completed some roofing work on an extension and I'm not happy with the quality of the weathering. All the rain this week has been a blessing in disguise since it's showing stuff up. One area is detail where a tile hung (plain tile) gable timber wall upstand joins a shallow pitch roof above (single lap tiles above).

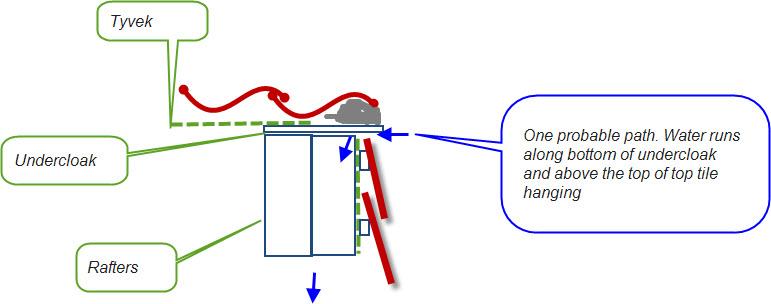

Builder has done it like in this picture.

Water (wind driven but mostly just surface capillary) is running horizontally beneath the undercloak and entering the ~5mm gap above the top hung tile. From there, it continues along the undercloak till it ends up inside the roof at the rafter, runs down and makes rafter wet.

The Tyvek on the gable is very roughly cut off at the top of the rafter, there is no overlap to the top of the rafter.

Does the undercloak need some sort of drip?

- or is there another normal way to prevent this happening?

I need to get him to re-do the gable so I need a good fix.

My builder has last week completed some roofing work on an extension and I'm not happy with the quality of the weathering. All the rain this week has been a blessing in disguise since it's showing stuff up. One area is detail where a tile hung (plain tile) gable timber wall upstand joins a shallow pitch roof above (single lap tiles above).

Builder has done it like in this picture.

Water (wind driven but mostly just surface capillary) is running horizontally beneath the undercloak and entering the ~5mm gap above the top hung tile. From there, it continues along the undercloak till it ends up inside the roof at the rafter, runs down and makes rafter wet.

The Tyvek on the gable is very roughly cut off at the top of the rafter, there is no overlap to the top of the rafter.

Does the undercloak need some sort of drip?

- or is there another normal way to prevent this happening?

I need to get him to re-do the gable so I need a good fix.