- Joined

- 17 Feb 2019

- Messages

- 207

- Reaction score

- 13

- Country

Hi all,

We had a 35kw Worcester Bosch Greenstar 8000 life system boiler installed a few months back. It's CH only and powering 15 rads of about 30kw or so at T50. All the rads and piping are all new too. Basically a full new system.

We're facing a problem where we cant get all the rads hot, had them balanced 3 times and no matter what there's always a small few that aren't heating up right.

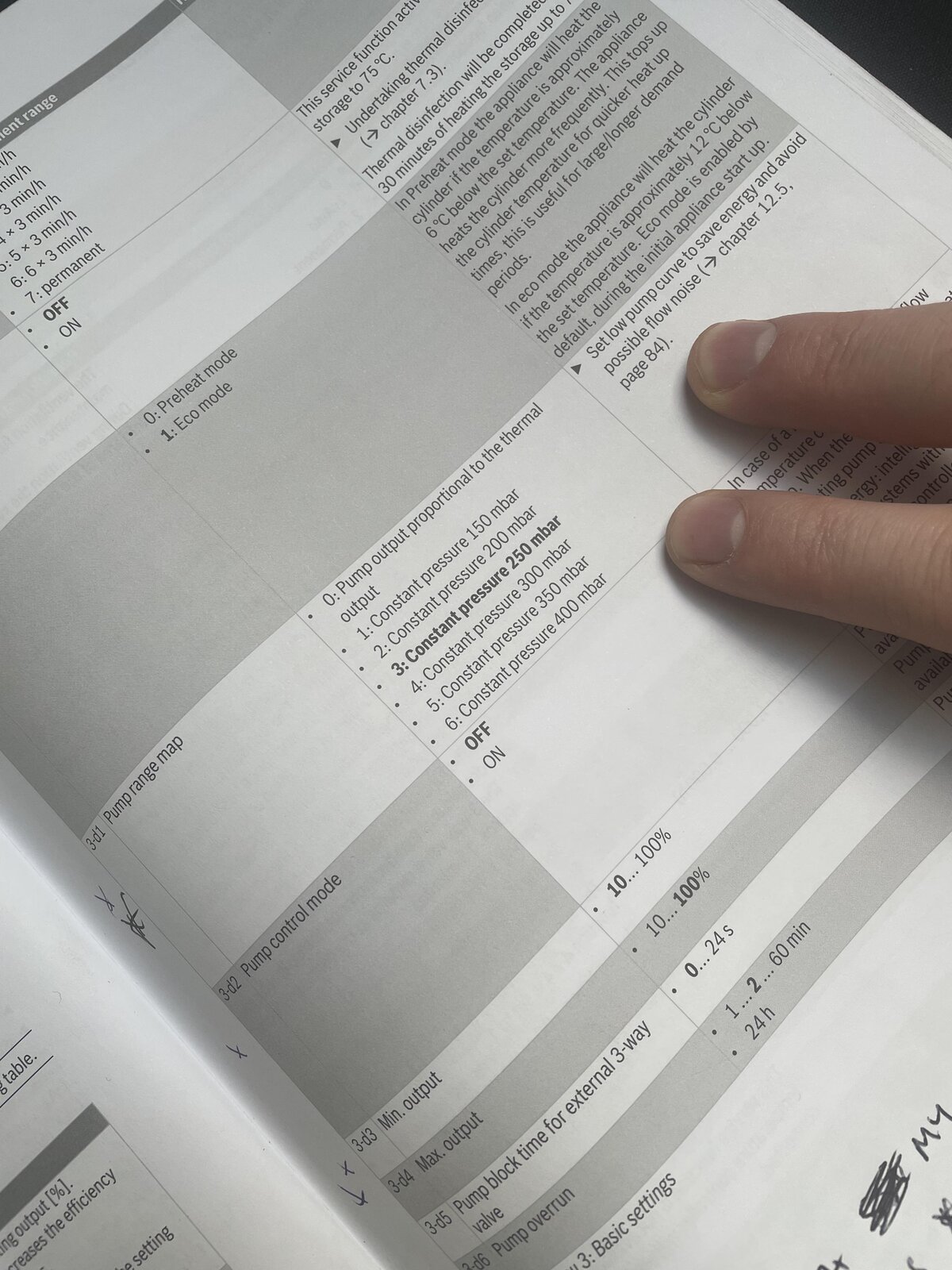

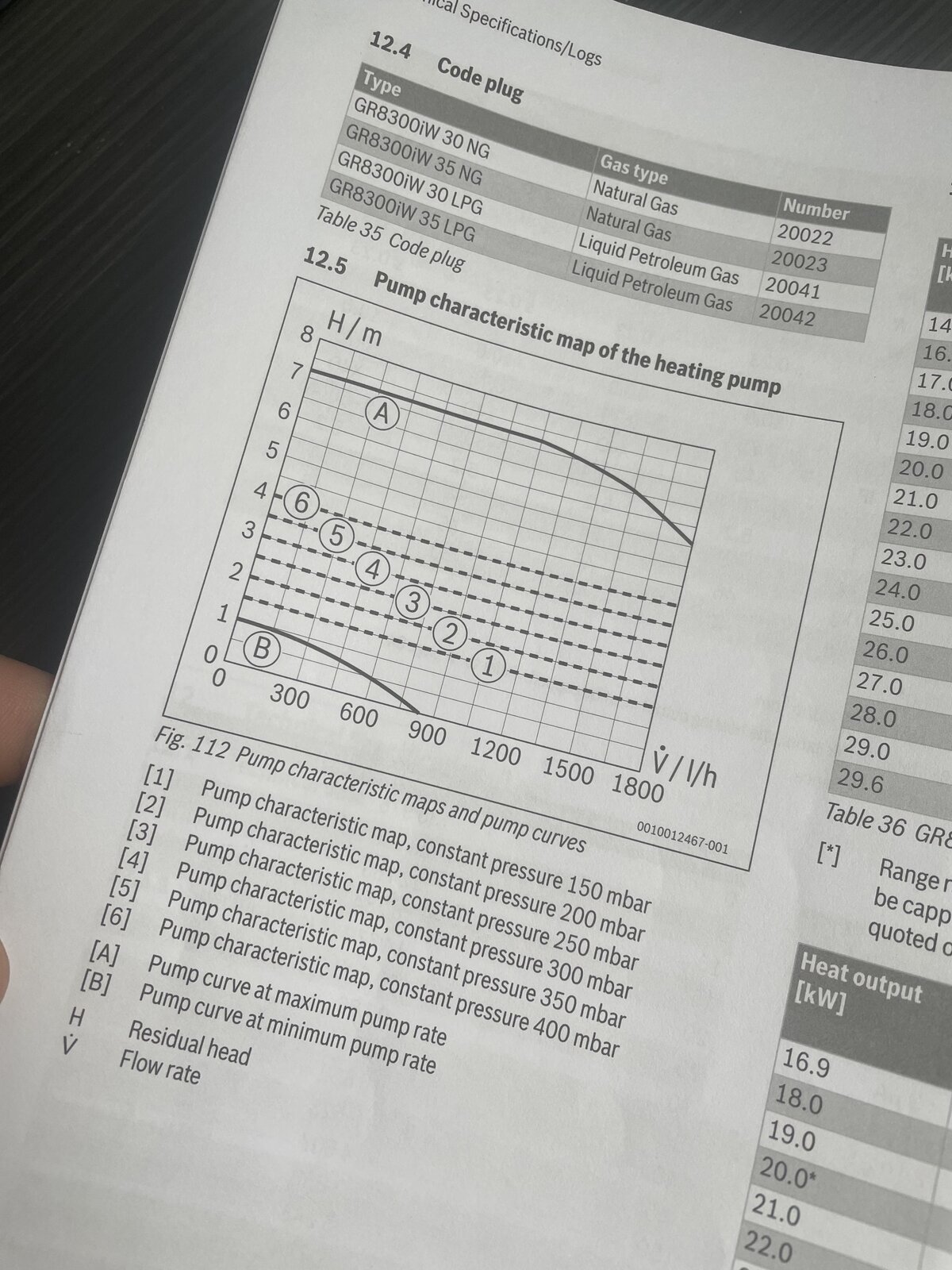

On doing a bit of digging online I saw one of the things to look at in this case would be pump speed. With it being a system boiler its internal and controlled via the boiler itself. I took a quick look at the manual and wondered if based on the number and kilowattage of radiators mentioned above, what setting should this be put to? (it's currently on default of 250mbar). Wondering if it'd be better to simply up it, or try option 0 which appears to then work via a curve thats proportional to the thermal output (which seems way more complicated for a DIY'er like me!)

pics of settings below

thanks all look forward to hearing your thoughts and helping me solve this tepid house..!

Geddy

We had a 35kw Worcester Bosch Greenstar 8000 life system boiler installed a few months back. It's CH only and powering 15 rads of about 30kw or so at T50. All the rads and piping are all new too. Basically a full new system.

We're facing a problem where we cant get all the rads hot, had them balanced 3 times and no matter what there's always a small few that aren't heating up right.

On doing a bit of digging online I saw one of the things to look at in this case would be pump speed. With it being a system boiler its internal and controlled via the boiler itself. I took a quick look at the manual and wondered if based on the number and kilowattage of radiators mentioned above, what setting should this be put to? (it's currently on default of 250mbar). Wondering if it'd be better to simply up it, or try option 0 which appears to then work via a curve thats proportional to the thermal output (which seems way more complicated for a DIY'er like me!)

pics of settings below

thanks all look forward to hearing your thoughts and helping me solve this tepid house..!

Geddy