I've had an extension built, and while the house was being battered decided to completely re-plumb everything because the previous system was old, a bit temperamental and a pain to maintain (gravity hot water, gas-fired Rayburn, no service valves, pump inaccessible).

The builder has appointed a plumber, but I'm becoming nervous about his competence. However, maybe I'm wrong and he's right, so I'd welcome views about how concerned I should be:

1: Condensate drain from the new Worcester Bosch system boiler boiler is routed out through the external wall it's mounted on, drops vertically about 2m, then turns horizontal, runs about 1m, round the corner of the building and another 0.5m until it discharges above the grate at the bottom of a downpipe (which goes to a soakaway under my lawn). However, the boiler is wall-mounted about a metre from where the kitchen sink will be. It's above a worksurface that the sink is in. I think it should drop from the boiler, turn below worktop and connect to the waste from the sink. I queried the external drain with the plumber and he said it had to go external, it was not possible (I think he said not permitted) to run it internally.

2: Heating is S-plan with two zones plus hot water, so there are three 2-port valves and a bypass. The bypass is just 15mm copper with a manual turn-wheel valve on it. I thought building regs guidance recommended (though admittedly not mandated) an automatic bypass on all new systems.

3: The boiler has been in about two weeks and I haven't heard the pump stop yet. Hot water is off, heating is turned down (12C - the house is still unoccupied), but the pump runs continuously. I go in every couple of days to see how things are progressing (normally evenings when builder etc already left) and have noticed that the pump is always running, though I've practically never seen the boiler burner firing. The plumber says it's fine, it's just the pump has an over-run time, but I'm sure I've been there when it has been running more than 30 minutes (and maybe as much as an hour) without any gas being burnt. Does it really have an over-run measured in hours?

4: I asked for a filter on the primary. He's put in a Fernox TF1. He's put it in the flow from the boiler and put it in with the arrow pointing opposite to the flow of water. In the return is preferred, I believe, but maybe flow is OK. However, surely the arrow must point the direction the water flows? He says he's checked with Fernox technical support and they say it's OK the way round he's put it. If the flow direction doesn't matter, why have arrows on it? Why all the coloured washers (which he doesn't seem to have used, though it is not orientated in the flow direction it comes out of the box).

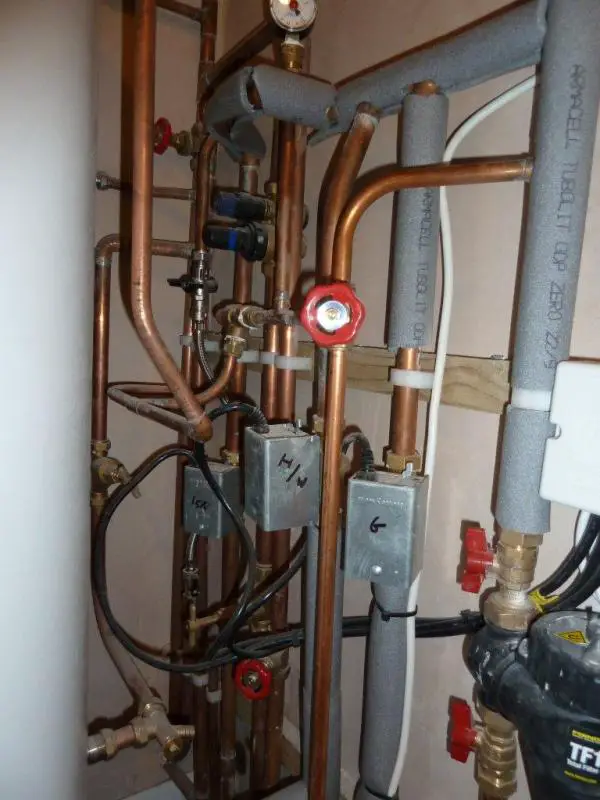

5: I explicitly specified a larger- than-usual cupboard for the hot water cylinder (it's 1m x 1.2m in plan) and explicitly said I'd done so because I wanted the plumbing components readily accessible and readily maintainable, but what I've got is a rats-nest tangle of pipes and valves at tight to one side of the cupboard and a cylinder most of the way to the other side with pipes spanning the gap between.

How worried should I be about the stuff I can't see under floors and in walls and the stuff I don't know anything about so don't know what's right?

The builder has appointed a plumber, but I'm becoming nervous about his competence. However, maybe I'm wrong and he's right, so I'd welcome views about how concerned I should be:

1: Condensate drain from the new Worcester Bosch system boiler boiler is routed out through the external wall it's mounted on, drops vertically about 2m, then turns horizontal, runs about 1m, round the corner of the building and another 0.5m until it discharges above the grate at the bottom of a downpipe (which goes to a soakaway under my lawn). However, the boiler is wall-mounted about a metre from where the kitchen sink will be. It's above a worksurface that the sink is in. I think it should drop from the boiler, turn below worktop and connect to the waste from the sink. I queried the external drain with the plumber and he said it had to go external, it was not possible (I think he said not permitted) to run it internally.

2: Heating is S-plan with two zones plus hot water, so there are three 2-port valves and a bypass. The bypass is just 15mm copper with a manual turn-wheel valve on it. I thought building regs guidance recommended (though admittedly not mandated) an automatic bypass on all new systems.

3: The boiler has been in about two weeks and I haven't heard the pump stop yet. Hot water is off, heating is turned down (12C - the house is still unoccupied), but the pump runs continuously. I go in every couple of days to see how things are progressing (normally evenings when builder etc already left) and have noticed that the pump is always running, though I've practically never seen the boiler burner firing. The plumber says it's fine, it's just the pump has an over-run time, but I'm sure I've been there when it has been running more than 30 minutes (and maybe as much as an hour) without any gas being burnt. Does it really have an over-run measured in hours?

4: I asked for a filter on the primary. He's put in a Fernox TF1. He's put it in the flow from the boiler and put it in with the arrow pointing opposite to the flow of water. In the return is preferred, I believe, but maybe flow is OK. However, surely the arrow must point the direction the water flows? He says he's checked with Fernox technical support and they say it's OK the way round he's put it. If the flow direction doesn't matter, why have arrows on it? Why all the coloured washers (which he doesn't seem to have used, though it is not orientated in the flow direction it comes out of the box).

5: I explicitly specified a larger- than-usual cupboard for the hot water cylinder (it's 1m x 1.2m in plan) and explicitly said I'd done so because I wanted the plumbing components readily accessible and readily maintainable, but what I've got is a rats-nest tangle of pipes and valves at tight to one side of the cupboard and a cylinder most of the way to the other side with pipes spanning the gap between.

How worried should I be about the stuff I can't see under floors and in walls and the stuff I don't know anything about so don't know what's right?