Gary..

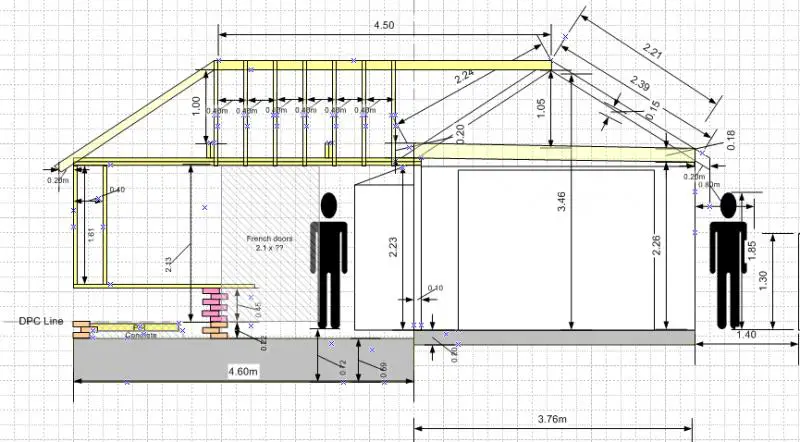

Timber frame Target 0.28 W/m2K.

R + Resistance

From outside to inside.

External air 0.06 R

22mm timber cladding .0,17 R

25x50mm Vertical batten to form 25mm cavity 0.18

Permeable felt.

12mm ply or OSB 0.09 R

47x125 Stud work

12.5 foil backed plaster board 0..25 R

Internal pressure 0,12 R

Inside studs 100mm Celotex 4.54 R

Leaves 25 mm low emisavity cavity between celotex and plasterboard for service void

According to our figures total R .is 5.41 m2K/W. Allow a generous percentage of 20% for cold bridging as there is lot of it, equals 4.32 m2K/W, which equals U Value of 0.23 W/m2K. Will give you more detail within next two days.

Regards oldun

Timber frame Target 0.28 W/m2K.

R + Resistance

From outside to inside.

External air 0.06 R

22mm timber cladding .0,17 R

25x50mm Vertical batten to form 25mm cavity 0.18

Permeable felt.

12mm ply or OSB 0.09 R

47x125 Stud work

12.5 foil backed plaster board 0..25 R

Internal pressure 0,12 R

Inside studs 100mm Celotex 4.54 R

Leaves 25 mm low emisavity cavity between celotex and plasterboard for service void

According to our figures total R .is 5.41 m2K/W. Allow a generous percentage of 20% for cold bridging as there is lot of it, equals 4.32 m2K/W, which equals U Value of 0.23 W/m2K. Will give you more detail within next two days.

Regards oldun