Before i go any further, i need to get a copy of BS 4163, see it was updated this year.

Thanks for all the replys, am sure i will be back to this later unless the machinery break situation scuppers the plans

The machinery breaks are very easy to fit, they work by reversing the field in the motor to bring it to a standstill, all electric, no mechanism involved. If they have the machines allready then hit stop and time the rundown, if it stops inside 10secs you are Ok without a break

We use a make called DRIV-LOCK, can't find a site on them but get then via CEF, its a box about as big as a contactor enclosure.

Better if they can buy breaked machines with all the requisite stops etc, Axminster Power Tools Educational do a good range a very good prices, table saw c£1000, very large bandsaw c£1500, good pillar drills c£800 all fully specced for BS4163 ready to instal.

P&J or Nederman are the people to talk to about LEV (dust extraction), unless you have flow meters dont try to do that youself

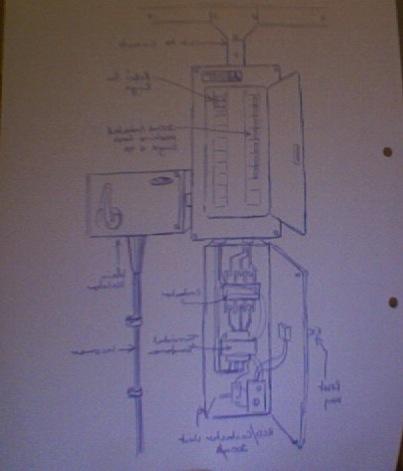

We generally run round the workshop in galv trunking and drop down in 20mm galv conduit to MEM isolators (I prefer the excel range because they last and last).

If we wire fixed I generally use spiralised steel flexible conduit and SY if its a plug and socket affair, MICC to run to brazing hearths for obvious reasons.

Prefer to have 13A sockets over benches hanging, Brennenstuhl make a 6way pendant socket outlet (available from Axminster) or a laboratory style ped box if the socket must be on a bench.

If you are doing kick stops, and you will, use Klockner-Moeller, they stand up to abuse, avoid the Craptree ones like the plague, I fitted a dozen and 10 had been smashed in a week, if they want de-luxe MEM do an ironclad kick stop but at £50 a peice pricey.

You can get door latching switches and task lights from Axminster.

Hope this is all of use, you will find BS4163 an interesting read, it also specs the clearance between machines and tables and other machines, which has scuppered plans in the past, the average charge from the big two in school workshops would be about £10K to fully wire a workshop inc parts, if you go down MEM route you can happily blow £4K on bits.

If you enjoy it get into the annual risk assesment game, £30/machine is what I charge and thats cheap, workshop of say 20 machines, half a days work - kerching (the big 2 charge about £60 a pop!!).