I'm just about to start on a DIY project to fit a new cloakroom and had a few plumbing questions if any of you could kindly help with:

Is this pipe here likely to be solvent welded in place or will it just be a pushfit connection. My neighbour has a flexible connector here now so I imagine at some point it was replaced.

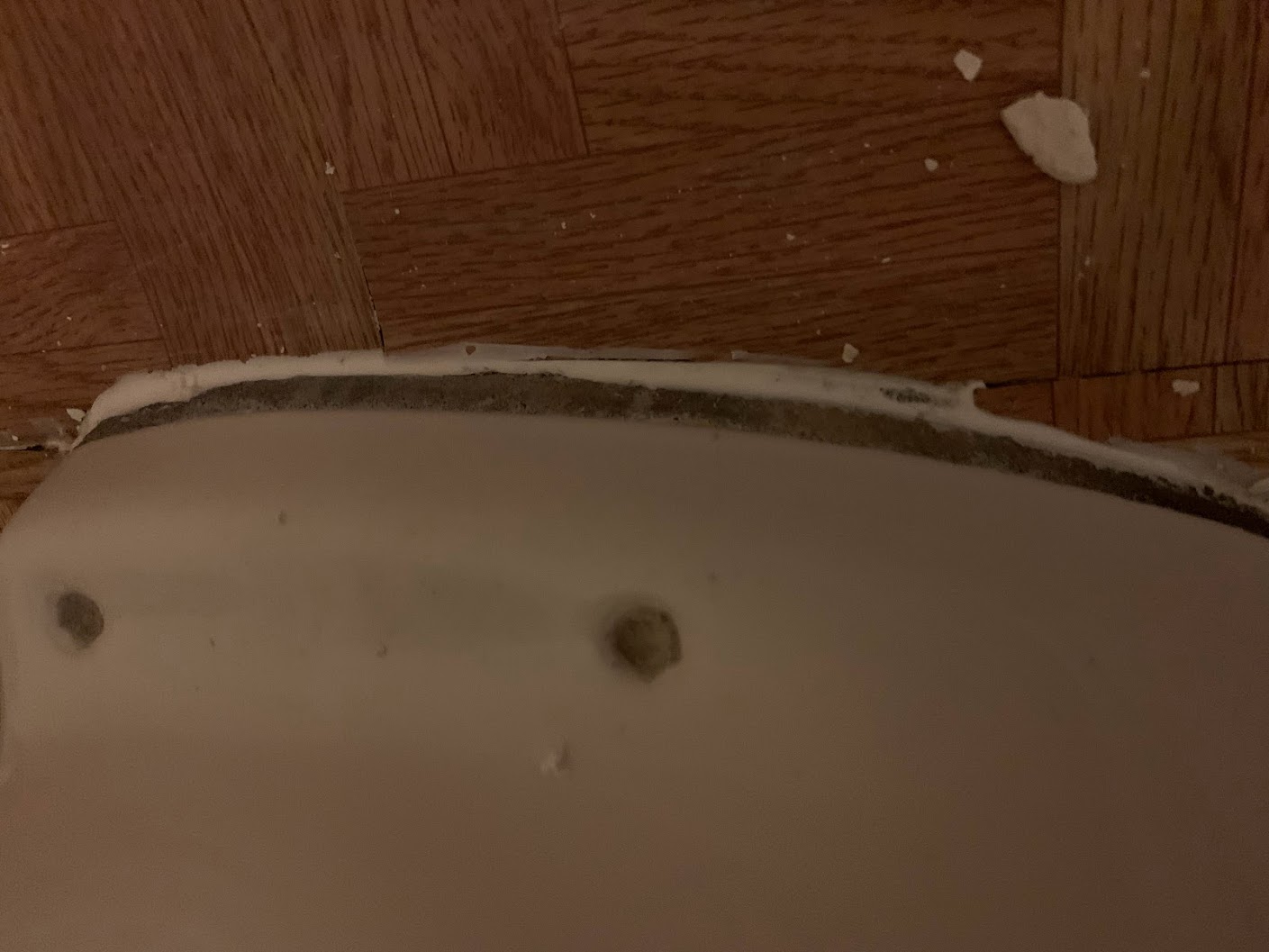

Does it look like the toilet has been cemented in place? If so is there an easy way to remove this or will it just be a case of smashing up the toilet. I'm not sure if there are any screws in place - it looks like there is cement in the screw holes too.

I'm going to be running 32mm waste pipe from the sink at about a 2.5m distance (about 0.5m distance greater than it is at the moment). Will adding an AAV (such as https://www.amazon.co.uk/gp/product/B00NW53XD6/ref=ox_sc_act_title_1?smid=A5TFJHPH9QD6Q&psc=1) solve the 1.7m distance issue? It's not going to be easy to change to 40mm as a 32mm reducer has been solvent welded to the stack.

Thanks for any help.

Is this pipe here likely to be solvent welded in place or will it just be a pushfit connection. My neighbour has a flexible connector here now so I imagine at some point it was replaced.

Does it look like the toilet has been cemented in place? If so is there an easy way to remove this or will it just be a case of smashing up the toilet. I'm not sure if there are any screws in place - it looks like there is cement in the screw holes too.

I'm going to be running 32mm waste pipe from the sink at about a 2.5m distance (about 0.5m distance greater than it is at the moment). Will adding an AAV (such as https://www.amazon.co.uk/gp/product/B00NW53XD6/ref=ox_sc_act_title_1?smid=A5TFJHPH9QD6Q&psc=1) solve the 1.7m distance issue? It's not going to be easy to change to 40mm as a 32mm reducer has been solvent welded to the stack.

Thanks for any help.