Indeed, a deceptive photo.

It's a bypass but why you needing one on a Y-plan is unusual.

Do all your radiators have thermostatic radiator valves?

Not all, the hallway, utility, toilet don't, rest have.

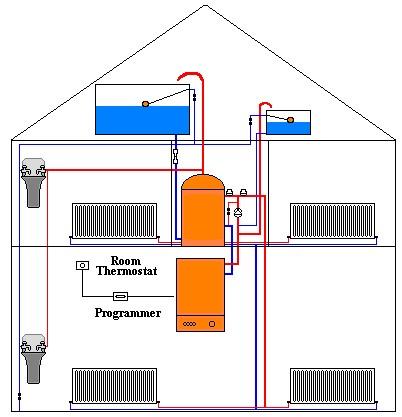

Below i have added a diagram i found which shows a similar set up to mine, only one i could find showing this bypass pipe/valve.