Hi All,

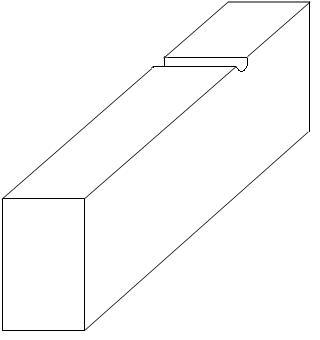

I'm looking for a bit of advice on the best way to go about cutting a groove in some timber, similar to that shown in the sketch below (exact profile is not relevant - its just a path to run cable through). The timber represents the joists in the frame I have built to lay decking boards down onto. I will be running cable (with the appropriate protection) in order to install decking lights. I settled on a groove in the upper edge of the timber, rather than drilling through holes, as it means that replacing the cabling will be much easier as I can just lift it up - no feeding through holes. It also means it will be easier to treat the exposed wood, as I have been doing with the end grains where I have cut the wood.

Obviously a router would be a good option but I dont own one and want to buy one at present. After some searching I have come across these wood rasps made by bosch, has anyone used these before - will they give a cleanish cut quickly - or will I be grinding at the wood for hours? (I will be using them in a mains power drill)

Thanks for the help/advice!

I'm looking for a bit of advice on the best way to go about cutting a groove in some timber, similar to that shown in the sketch below (exact profile is not relevant - its just a path to run cable through). The timber represents the joists in the frame I have built to lay decking boards down onto. I will be running cable (with the appropriate protection) in order to install decking lights. I settled on a groove in the upper edge of the timber, rather than drilling through holes, as it means that replacing the cabling will be much easier as I can just lift it up - no feeding through holes. It also means it will be easier to treat the exposed wood, as I have been doing with the end grains where I have cut the wood.

Obviously a router would be a good option but I dont own one and want to buy one at present. After some searching I have come across these wood rasps made by bosch, has anyone used these before - will they give a cleanish cut quickly - or will I be grinding at the wood for hours? (I will be using them in a mains power drill)

Thanks for the help/advice!