Hi,

Thanks for a great forum. I have spent a number of hours on here already.

I have recently moved into a new house (well new to me... but house is 30 years old) and need \ want to make some changes.

Firstly I want to install a shower pump to power mixer shower in main bathroom and a new mixer shower to replace an electric shower in en-suite. I have ordered a Salamander ESP 100 CPV pump and S-Flange for the cylinder. The shower in the main bathroom is already a power shower but the pump has given in and I cant get a replacement so I already have a dedicated 22mm feed from my loft storage tanks (2 large linked tanks), 160l cylinder and the necessary electrics (will fit 5amp fused socket).

I plan to locate the pump on the floor of the airing cupboard. The main shower is behind the wall of the airing cupboard so should not be a problem to hook up.

My first question is about supplying the en-suite shower. Currently the shower is fed from a 15mm main taken off the feed to the storage tanks and run the length of the house (+- 10m) through the loft and down from the ceiling. I will obviously disconnect this line and feed the shower with 2 x 22mm feeds from the pump. Is there a problem with me running the new hot and cold 22mm pumped lines through the loft too? Or should they run under the floor and come up into the shower? I plan to make all visible pipework in copper and either loft or under floor in plastic barrier pipe. The loft run I think would be the simplest for me to do as I don't have to lift a load of floor boards and its is easier for me to run the pipes down from the loft into the shower cubicle rather than up through the shower tray. I will eventually redo the en-suite room and will bury the pipes in the wall at that time but cant do it now.

My second question is about the water temp. The pump specifies a maximum temp of 65C but my cylinder does not have a thermostat. The water system is a gravity fed C-Plan and my boiler needs the hot water to be on in order to supply the radiators. Is there any risk of the water temp getting too hot? If yes is there anything I can do to control the temp of the supply to the pump?

My last question... Is it worth me spending time and money in changing my system from gravity fed to pumped? What are the benefits? I believe my boiler (danesmoor 20/25) can be configured in Y-Plan.

Sorry this is so long... I realise a plumber would be best for these jobs but I like doing them myself.

Thanks

Warren

Thanks for a great forum. I have spent a number of hours on here already.

I have recently moved into a new house (well new to me... but house is 30 years old) and need \ want to make some changes.

Firstly I want to install a shower pump to power mixer shower in main bathroom and a new mixer shower to replace an electric shower in en-suite. I have ordered a Salamander ESP 100 CPV pump and S-Flange for the cylinder. The shower in the main bathroom is already a power shower but the pump has given in and I cant get a replacement so I already have a dedicated 22mm feed from my loft storage tanks (2 large linked tanks), 160l cylinder and the necessary electrics (will fit 5amp fused socket).

I plan to locate the pump on the floor of the airing cupboard. The main shower is behind the wall of the airing cupboard so should not be a problem to hook up.

My first question is about supplying the en-suite shower. Currently the shower is fed from a 15mm main taken off the feed to the storage tanks and run the length of the house (+- 10m) through the loft and down from the ceiling. I will obviously disconnect this line and feed the shower with 2 x 22mm feeds from the pump. Is there a problem with me running the new hot and cold 22mm pumped lines through the loft too? Or should they run under the floor and come up into the shower? I plan to make all visible pipework in copper and either loft or under floor in plastic barrier pipe. The loft run I think would be the simplest for me to do as I don't have to lift a load of floor boards and its is easier for me to run the pipes down from the loft into the shower cubicle rather than up through the shower tray. I will eventually redo the en-suite room and will bury the pipes in the wall at that time but cant do it now.

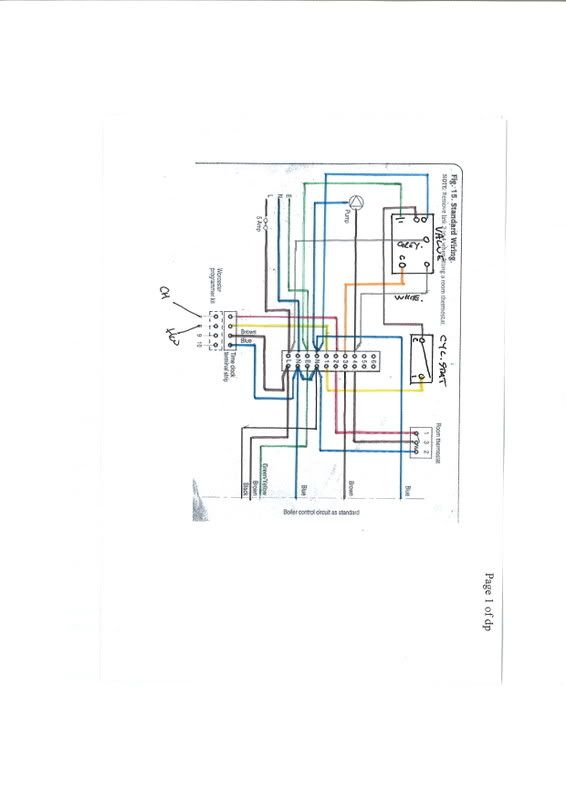

My second question is about the water temp. The pump specifies a maximum temp of 65C but my cylinder does not have a thermostat. The water system is a gravity fed C-Plan and my boiler needs the hot water to be on in order to supply the radiators. Is there any risk of the water temp getting too hot? If yes is there anything I can do to control the temp of the supply to the pump?

My last question... Is it worth me spending time and money in changing my system from gravity fed to pumped? What are the benefits? I believe my boiler (danesmoor 20/25) can be configured in Y-Plan.

Sorry this is so long... I realise a plumber would be best for these jobs but I like doing them myself.

Thanks

Warren