Hey,

I'm looking to put recessed lights in my decking and sleepers* and the manual has 2 options for fitting them. I'd prefer option 2:

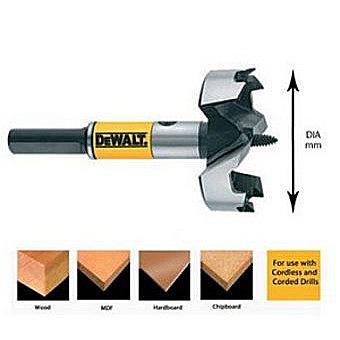

"Drill a 76mm diameter hole. Machine a 97mm diameter by 13mm deep counterbore."

Can someone advise where to get both bits, specifically the latter one.

Thanks

*Regarding the sleepers, obviously they're solid all the way through, whereas decking is 'hollow' once you're through the 25mm thickness or so, so how would a recessed light work in this scenario. Is it a bad/impossible idea?

http://www.saxbylighting.com/instructions/25702.pdf

I'm looking to put recessed lights in my decking and sleepers* and the manual has 2 options for fitting them. I'd prefer option 2:

"Drill a 76mm diameter hole. Machine a 97mm diameter by 13mm deep counterbore."

Can someone advise where to get both bits, specifically the latter one.

Thanks

*Regarding the sleepers, obviously they're solid all the way through, whereas decking is 'hollow' once you're through the 25mm thickness or so, so how would a recessed light work in this scenario. Is it a bad/impossible idea?

http://www.saxbylighting.com/instructions/25702.pdf