Hello,

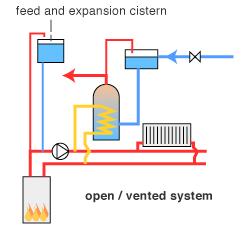

Would someone be able to look at the arrangement of pipes going into and out of the feeder/expansion cistern in my loft.

There are a couple of issues. First, is it ok for the water-out to be attached to the vent?

Secondly, the end of the vent inside the cistern sits below the water level. Is this ok?

Thanks for any ideas/comments

Joe

[/img]

[/img]

Would someone be able to look at the arrangement of pipes going into and out of the feeder/expansion cistern in my loft.

There are a couple of issues. First, is it ok for the water-out to be attached to the vent?

Secondly, the end of the vent inside the cistern sits below the water level. Is this ok?

Thanks for any ideas/comments

Joe