I've got what the Potterton (Suprima 60L) manual defines as a fully pumped sealed system. We've seen water coming out of the overflow outside and assume this is because the expansion vessel bladder has zero pressure (well I think that's why water is seen).

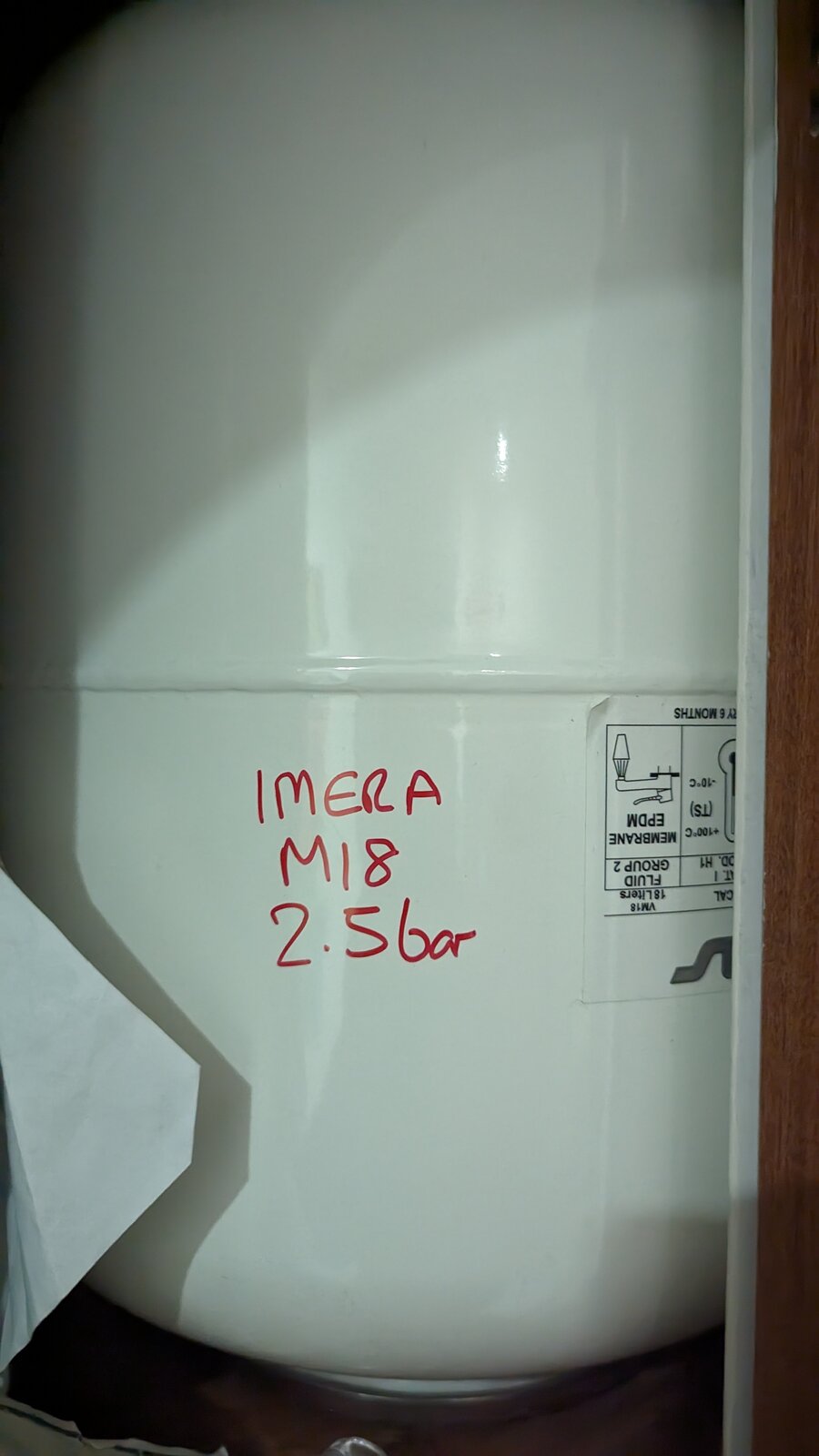

To pump this up I have turned off the mains, cracked open the hot and cold at the nearest outlet by the tank, and pumped to 2.5 bar. I 'think' it's an Imera M18 but am not 100% sure as it's in a wardrobe and obscured somewhat. However, am reasonably confident it does not hold pressure for long, so am wondering what to do. Can you replace the bladder, or do you replace the whole thing?

With the mains off and pressure released at the outlets, is it then empty/de-pressured and can just be replaced easily (looks one one nut only)?

Just read this link:

https://www.diynot.com/diy/threads/faqs.37170/

Indeed if I try to pump without shutting the mains off then there is pressure and water does come out of the Schrader valve.

Any help would be much appreciated.

To pump this up I have turned off the mains, cracked open the hot and cold at the nearest outlet by the tank, and pumped to 2.5 bar. I 'think' it's an Imera M18 but am not 100% sure as it's in a wardrobe and obscured somewhat. However, am reasonably confident it does not hold pressure for long, so am wondering what to do. Can you replace the bladder, or do you replace the whole thing?

With the mains off and pressure released at the outlets, is it then empty/de-pressured and can just be replaced easily (looks one one nut only)?

Just read this link:

https://www.diynot.com/diy/threads/faqs.37170/

Indeed if I try to pump without shutting the mains off then there is pressure and water does come out of the Schrader valve.

Any help would be much appreciated.