i have a garage roof to do with epdm which is joined to next doors garage which has been recently felted what is the best way to join them down the middle?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

joining epdm to existing felt roof?

- Thread starter pmr1983

- Start date

Sponsored Links

Are you boarding over your existing felt or slicing the felt between the two roofs and removing the felt your side, then reboarding?

i will be removing the felt from my side then reboading

EPDM is best stand-alone and not joined to a felted roof. This isn't the way they tell you to do it on the EPDM course, but its what the lads do.

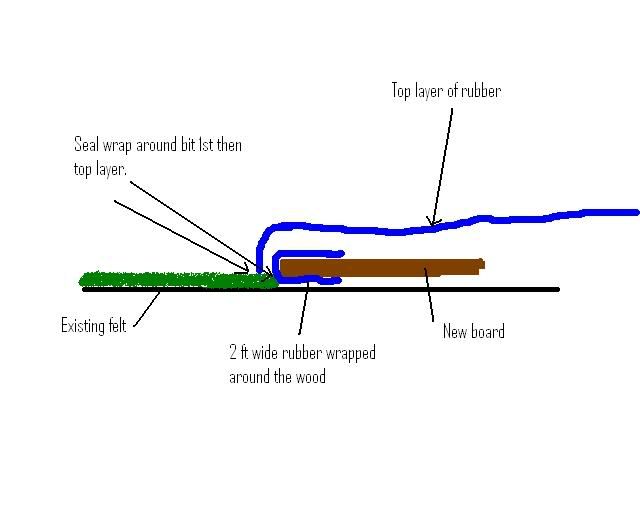

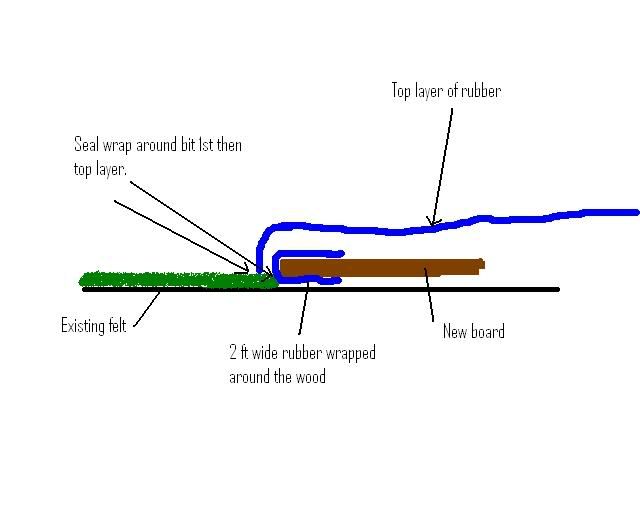

As long as you have done a perfect clean straight slice between the two roofs, before you lay your board down 1st glue some rubber down overlapping a foot under and foot over, then screw the board down tight, screwing well near the edge. Your board must be butted hard against the straight cut felt.

Run a bead of leadmate or lead sealant between the wrapped around rubber and the felt edge. Let it dry whilst u board the rest of the roof. Don't use silicone!

Then you lay the rubber as normal overlapping onto the felt slightly and then seal it again with lead mate.

Finally you then put a length of epdm seam tape over the join and then onto the other roof, use water based glue as the solvent stuff reacts with the oils in the felt. the other roof has to be as clean and dry as poss.

You shouldnt really join rubber to felt, its an absolute pain and only do it if the join is at the highest point on the fall.

See my excellent drawing, lol (which doesnt show final seam tape join)

As long as you have done a perfect clean straight slice between the two roofs, before you lay your board down 1st glue some rubber down overlapping a foot under and foot over, then screw the board down tight, screwing well near the edge. Your board must be butted hard against the straight cut felt.

Run a bead of leadmate or lead sealant between the wrapped around rubber and the felt edge. Let it dry whilst u board the rest of the roof. Don't use silicone!

Then you lay the rubber as normal overlapping onto the felt slightly and then seal it again with lead mate.

Finally you then put a length of epdm seam tape over the join and then onto the other roof, use water based glue as the solvent stuff reacts with the oils in the felt. the other roof has to be as clean and dry as poss.

You shouldnt really join rubber to felt, its an absolute pain and only do it if the join is at the highest point on the fall.

See my excellent drawing, lol (which doesnt show final seam tape join)

Sponsored Links

hi thanks for the advise, there is hardly any fall if any on the roof it's flat and i will also be removing the old boards (rotten) so the new boards will be just below nextdoors felt level with there boards so they wont quite but up to the felt like your picture shows does this make any difference or will this method still work?

It will work if you take your time. Is there anyway the neighbours can have it done? Maybe if you cost up the materials and pay yourself £150 then its a bit of extra money for your work but then at least you have peace of mind.

Best way is as has been said before, get neighbour to have theirs done and save a bit of money in the long run.

One way around it that we have been informed of for the membrane we use (Rhepanol fk) is to apply a liquid coating system (Sealoflex) at the join. These two products are supplied by the same company (SIG) and is covered under their warranty.

One way around it that we have been informed of for the membrane we use (Rhepanol fk) is to apply a liquid coating system (Sealoflex) at the join. These two products are supplied by the same company (SIG) and is covered under their warranty.

Hi MW Roofline!

Why do you use that way to join the roofs?

What effect does it have?

Cheers

Tony.

Why do you use that way to join the roofs?

What effect does it have?

Cheers

Tony.

- Joined

- 9 Feb 2011

- Messages

- 6

- Reaction score

- 2

- Country

you can do this and it will work! its not ideal i have to say, but we have done quite a few epdm to felt roofs. (and we have not had a come back yet) the best way i have found is to replace your boards, glue down your rubber system, leaving a six inch overlap over the felt roof. make sure the felt roof is dry (we use a hairdryer that we have just for this purpose!). remove all loose dirt, dust and grime. you will then need a tin of acrypol fibre based resin. put plenty down on the felt side, not the rubber. build up a thick layer across the six inches where the rubber will sit. then lay the rubber down on to it, and press in. you will then need a length of slate batten (the thicker one). this needs to be screw fixed down to hold the rubber tight down. make sure its firmly fixed, certainly more so at the back of the roof where it pitches (i presume its a dormer?). the acrypol will push out and form a superb seal. then paint over the batten with the same material to protect it fromm rot. job done.

following the Acrypol answer - Have a look @ liquid plastics website - they sell similar, maybe better  stuff . Thanks to all the guys who replied - I`m still learning about this flat roofing, in preparation for mine over the kitchen - yes I could do it in lead, but it`s a bit pricey and heavy

stuff . Thanks to all the guys who replied - I`m still learning about this flat roofing, in preparation for mine over the kitchen - yes I could do it in lead, but it`s a bit pricey and heavy  and it might not stay long

and it might not stay long

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 9

- Views

- 5K