If one accepts that it is incredibly unlikely that supply pipes would introduce a non-earth potential, the MPB is merely joining two 'earths' together.

No it is not joining two earths together, It is joining an "earth" wire in the building to pipes outside the building that might be in contact with true ground.

OK, I was not totally explicit in my wording, for which I apologise, but this is really just playing with words. I was, of course, talking specifically about TT systems, and I perhape should have included the word '

effectively'. In other words, what I was saying was that, in such a system, if one accepts that it is incredibly unlikely that the supply pipes (or the TT earth electrode) would introduce a non-earth potential, then the MPB in such a system is

effectively joining together two points which are both usually at/close to earth potential.

The confusion arises because the word "earth" is used for what is no longer an "earth". The "earth" wire in a modern install is a protective circuit CPC and is derived in many cases from the incoming neutral. Hence it may not be at ground potential. Only in a modern TT install is the CPC true ground where it is connected to a rod driven into the ground.

Indeed, but I would again remind you that my comments you are discussing were specifically

about TT. As I've said previously, I have no problem with the concept of MPB in relation to systems other than TT, in which a fault external to the installation could result in the DNO's earth terminal having a potential very different from earth (hence different from the probable potential of supply pipes, hence potentially {excuse pun!} dangerous).

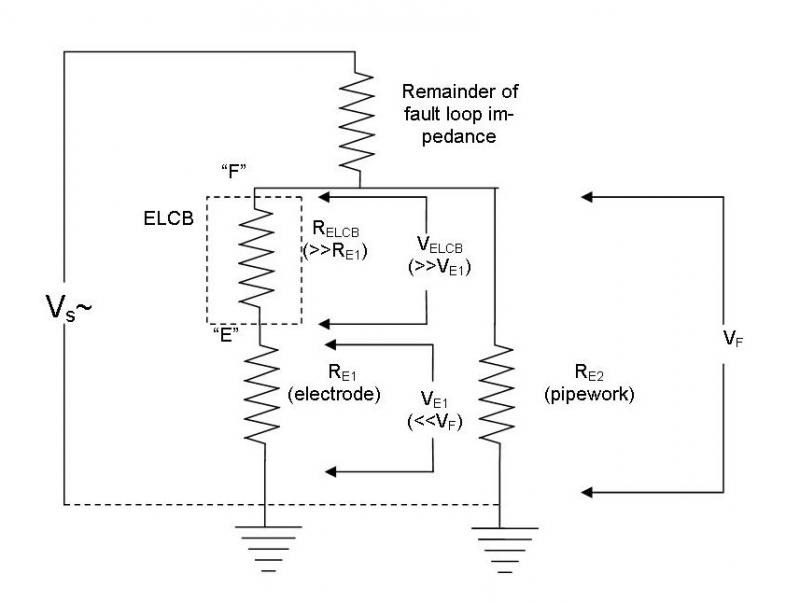

More confusion comes from the older TT installs where the CPC had to be isolated from ground if the voltage operated "earth" leakage breaker was to be effective as a safety device. It measured voltage between the CPC and the ground rod and if this became too high the trip operated.

Indeed, that's the very situation I inherited when I came to this property nearly 30 years ago, but I had that changed (to RCDs) immediately.

Even if there is an argument for having it (the only one I can think of being that vanishingly small probability that a supply pipe might introduce a non-earth potential),

It is the other way round. The supply pipe may introduce the true ground potential into a installation whose CPC ( "earth" wire " was not at ground potential

OK, maybe we are getting a little closer to a rationale for an MPB in a TT installation. As I keep saying, I really don't think one needs to consider the incredibly unlikely possibility that the earth electrode will itself introduce a non-earth potential (in the way that the DNO's earth terminal may, in systems other than TT - as you discuss below). However, that leaves us having to consider faults

within the installation.

Given the non-zero impedance path to earth from the earth electrode (hence MET), a fault in the installation which gives rise to a current in the CPC will obviously cause the potential of the earth electrode (hence MET) to rise above true earth - in which case this would indeed, mean that the potential of MET and supply pipes (probably earth potential) would probably be different in the absence of (explicit or implicit) bonding. Maybe this is the thinking behind the concept of MPB in a TT installation? If so, one could debate how essential that really is, given that the regulations effectively require the presence of protective devices which limit how high the potential of the earth electrode/MET can rise (as the result of something happening within the installation - be it a fault or a human bondy in the current path) to a level deemed to be safe (~50V for a limited time). Maybe it's just belt-and-braces.

I still cannot think of a logical basis for trying to decide what cable size to use (e.g. for deciding that it should be at least half the size of the earthing conductor).

Where the CPC is derived from the neutral and the supply pipe is metallic and in good contact with ground then in the event of a network fault the current in the bonding cables could be very high as it forms an un-intentional but effectively part of the alternative route for current in the network neutral to return to the sub station.

You again seem to be missing the point that the comments of mine you are discussing were specifically about TT systems. I have discussed the very point you make, agreeing that this is a good reason for having robust MPB with a system other than TT. It's with TT that I have a bit of a problem. I also wrote (in my most recent post) that the fact that the resultant fault current in a bonded system would necessarily flow through both the earthing conductor and the MPB - which is not necessarily a logical basis for saying that one can be half the size of the other.

Kind Regards, John