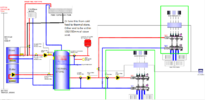

You might increase the pipe stat to 90/95c and see what kind of circulation you get with gravity only after lighting the fire, you definitely should get circulation through the dump rad and maybe some through the store. Also check the F&E tank.

There should really be a cold feed teed in just after the store vent pipe, that should stop the pumping over.

There should really be a cold feed teed in just after the store vent pipe, that should stop the pumping over.