You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

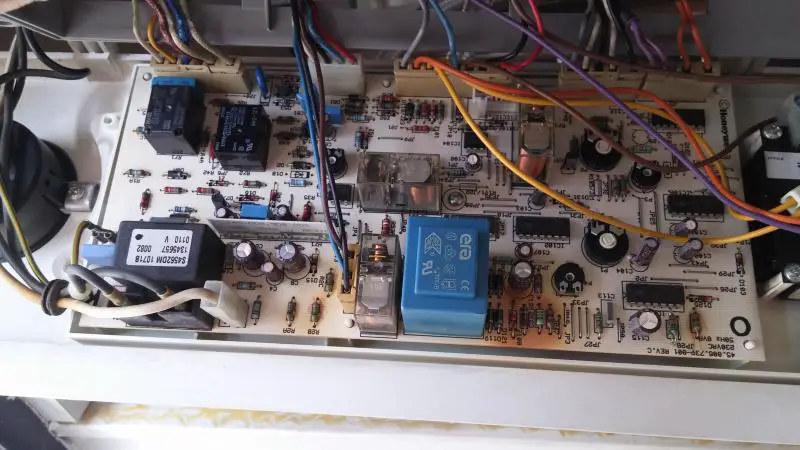

PCB Photo - Is this the problem?

- Thread starter greatia01

- Start date

Sponsored Links

That scorched area is the power supply components over heating, Happens on a lot of boiler PCBs. Most unlikely to be the reason the hot water is only warm.

Happens because the designers seem to forget the ambient temperature around the PCB is hotter than that of a room and yet they chose components suitable only for operation at room temperature or below.

You should not be working on the controls of a gas boiler.

One woman was literally blown away by her husband's DIY skill and knowledge of gas boilers.

Happens because the designers seem to forget the ambient temperature around the PCB is hotter than that of a room and yet they chose components suitable only for operation at room temperature or below.

You should not be working on the controls of a gas boiler.

One woman was literally blown away by her husband's DIY skill and knowledge of gas boilers.

J

james0james

While that cover is off,you could check that when you rotate the front thermostat knob for hot water,the corresponding black pod center insert also turns at the same time.

Try the heating thermostat knob first,this will show you what travel on black pod center to expect.

Try the heating thermostat knob first,this will show you what travel on black pod center to expect.

This is to test for broken spindle syndrome.

This is to test for broken spindle syndrome.

Sponsored Links

Ignore all the other advice, this is the part of the PCB that controls the gas valve and will be the cause of your poor hot water.

Now here is the rub, you will need a registered gas guy to fit a new one. It needs to be set up as, the ignition, ch gas rate and of course the hot water are all adjusted by settings on the PCB.

Now here is the rub, you will need a registered gas guy to fit a new one. It needs to be set up as, the ignition, ch gas rate and of course the hot water are all adjusted by settings on the PCB.

Ignore all the other advice, this is the part of the PCB that controls the gas valve and will be the cause of your poor hot water.

Now here is the rub, you will need a registered gas guy to fit a new one. It needs to be set up as, the ignition, ch gas rate and of course the hot water are all adjusted by settings on the PCB.

It's not the only reason why is hot water is poor, if you want to jump in feet first and buy a PCB then crack on. It's an expensive guess, most people would fault find first.

Just noticed your user name......makes sense now.

Pay attention to the solder on the pins of the cable connectors. These joints have to absorb the mechanical vibrations in the cable loom ( fan, flame turbulence etc etc ) and are going to be the first to fail. They fail with a circular crack in the solder all around the pin.I'd be checking for dry joints under the burnt areas of the PCB whilst it's out. (power = off), not that it has anything to do with the problem but because it's likely.

Repair of gas appliances is not a DIY activity

As an ex Group Service engineer, I'd put my experience over your soldering iron any day.

Yes, but a Group Service guy has a van full of parts which he is not paying for. And it may be quicker to change the PCB first just in case when there are seven more repairs to do during the day.

An independent engineer will ( should ) diagnose the fault first before incurring costs for the owner.

I would doubt that its a PCB fault in this case, although of course it always might be.

Tony

An independent engineer will ( should ) diagnose the fault first before incurring costs for the owner.

I would doubt that its a PCB fault in this case, although of course it always might be.

Tony

I've had this on our Compact 80. The fault was on the PCB. If you look at the PCB, the area to the right hand side of the transformer is discoloured, where components have got warm over time. There is an electrolytic capacitor which dries out, C105. I changed this and got another 2 years out of the PCB before the transformer TR100 then failed. Pity there are no circuit diagrams on the net, it would make fault finding on the PCB easier. We also had to restrict the flow of the hot tap to get hot water out of the boiler, and the pressure was down at 10, not 15.

How much do you charge per hour Tony! While you're setting up your oscilloscope and going to the merchants for a new component. I'd have diagnosed, changed the part, set up the pots and be gone in about half an hour.

Your three hours labour (estimated) isn't sounding such good value. Last one of these I charged £175 all in - your charges would be what?

Your three hours labour (estimated) isn't sounding such good value. Last one of these I charged £175 all in - your charges would be what?

I charge a fixed diagnostic fee of £84 in most cases.

But dont normally repair PCBs for customers except in exceptional circumstances.

So my charge would be £84 plus the PCB at perhaps £91 ?

Where possible I would bring a spare PCB with me if I suspected that.

So it might take me the target time of about an hour in total. But even if it did take three hours the charge would be the same.

Tony

But dont normally repair PCBs for customers except in exceptional circumstances.

So my charge would be £84 plus the PCB at perhaps £91 ?

Where possible I would bring a spare PCB with me if I suspected that.

So it might take me the target time of about an hour in total. But even if it did take three hours the charge would be the same.

Tony

I've had this PCB fault so many times now I don't even bother trying to diagnose it apart from a) check burner pressure b) replace PCB when adjusting the gas valve higher doesn't work. The scorch marks are the tell tale sign.

As mentioned though, it is not a DIY job as the new PCB is not set to any kind of factory setting and needs adjustment (it fits several different "Compact" models, both combi and system boiler).

As mentioned though, it is not a DIY job as the new PCB is not set to any kind of factory setting and needs adjustment (it fits several different "Compact" models, both combi and system boiler).

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 8

- Views

- 875

- Replies

- 15

- Views

- 10K

- Replies

- 1

- Views

- 2K