Good Morning

I'm in the processed of constructing a double skin block work porch and have now come to the roofing element of the project.

I would like some barge boards fitted to the front elevation / front gable to create a finish like so.

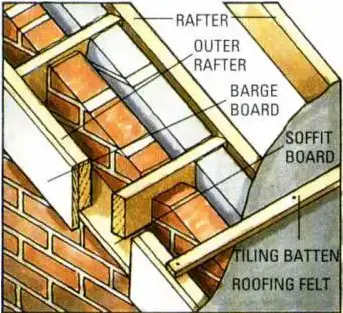

Unfortunately at the time of having the roof rafter fitted I did not have an external rafter fitted on the outside gable face (fixed through the block work and onto the inner rafter) to carry the barge board. I understand the detail should have looked something like this.

Instead what i have is this....

My thoughts are that it would be possible to mechanically fix a timber board to the front face of the block work and then through fix a barge board to that.

The cement board could fly over the front edge of the block work by 50mm giving the appearance that is desired.

Do we have any competent tradesmen that can advise if my proposal is a suitable solution or weather i need to have the additional rafter fitted to the external face (punching some holes through the constructed block work).

Advise is very much welcome and appreciated !

I'm in the processed of constructing a double skin block work porch and have now come to the roofing element of the project.

I would like some barge boards fitted to the front elevation / front gable to create a finish like so.

Unfortunately at the time of having the roof rafter fitted I did not have an external rafter fitted on the outside gable face (fixed through the block work and onto the inner rafter) to carry the barge board. I understand the detail should have looked something like this.

Instead what i have is this....

My thoughts are that it would be possible to mechanically fix a timber board to the front face of the block work and then through fix a barge board to that.

The cement board could fly over the front edge of the block work by 50mm giving the appearance that is desired.

Do we have any competent tradesmen that can advise if my proposal is a suitable solution or weather i need to have the additional rafter fitted to the external face (punching some holes through the constructed block work).

Advise is very much welcome and appreciated !