I will wire it all in as the remaha diagram tonight (involves some drilling through the walls to run the extra wires and get the permanent feed, which I think is why the fitter couldn't be bothered...)

Thing is though I don't see why that helps fix the fact that the switched live is not switching UNLESS the current setup is causing the components to fail - (boiler is firing up and running happily at the mo, as is the pump - though I agree the boiler controlling pump overrun is a good thing)

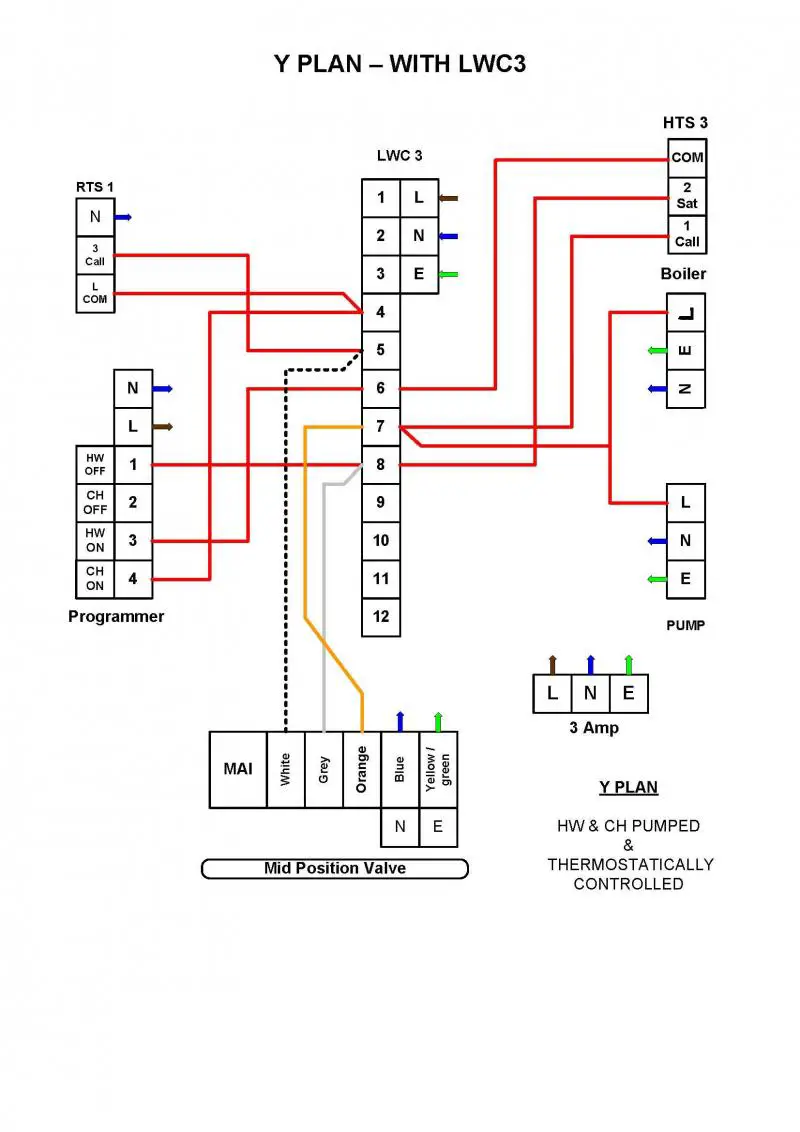

I'm trying to get the pdf of my wiring diagram saved as a picture so I can share it.

Thanks again for your thoughts (don't want my 2nd comment about the switched live to sound ungrateful), and I do agree it's a good idea to wire it all in exactly as the manufacturer describes then we all know what's what.

Thing is though I don't see why that helps fix the fact that the switched live is not switching UNLESS the current setup is causing the components to fail - (boiler is firing up and running happily at the mo, as is the pump - though I agree the boiler controlling pump overrun is a good thing)

I'm trying to get the pdf of my wiring diagram saved as a picture so I can share it.

Thanks again for your thoughts (don't want my 2nd comment about the switched live to sound ungrateful), and I do agree it's a good idea to wire it all in exactly as the manufacturer describes then we all know what's what.