I have a Worcester Greenstar 18Ri with a Wilo RS50 pump on an open vented system, the pump as approximately 2 mtrs of head.

I've been advised to keep the pump speed set at 2 to maintain the correct flow rate through the boiler, however with the pump set to 1 it is obviously much quieter and all the radiators still function properly.

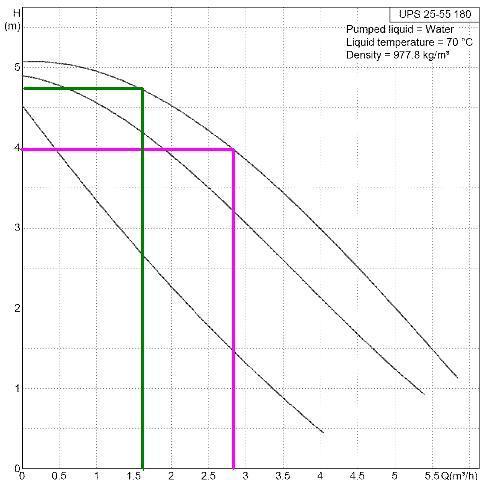

I can't seem to find the flow rate required by the boiler or the flow rate produced by the pump at it's three different settings.

Am I safe to run the pump at it's lowest setting or must I keep it on 2?

Any advice on this would be appreciated.

I've been advised to keep the pump speed set at 2 to maintain the correct flow rate through the boiler, however with the pump set to 1 it is obviously much quieter and all the radiators still function properly.

I can't seem to find the flow rate required by the boiler or the flow rate produced by the pump at it's three different settings.

Am I safe to run the pump at it's lowest setting or must I keep it on 2?

Any advice on this would be appreciated.