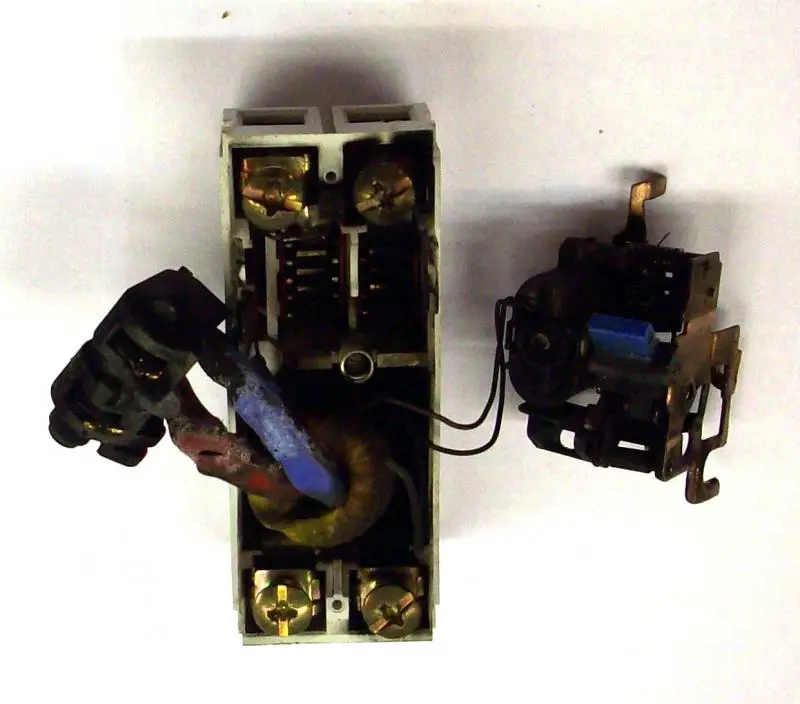

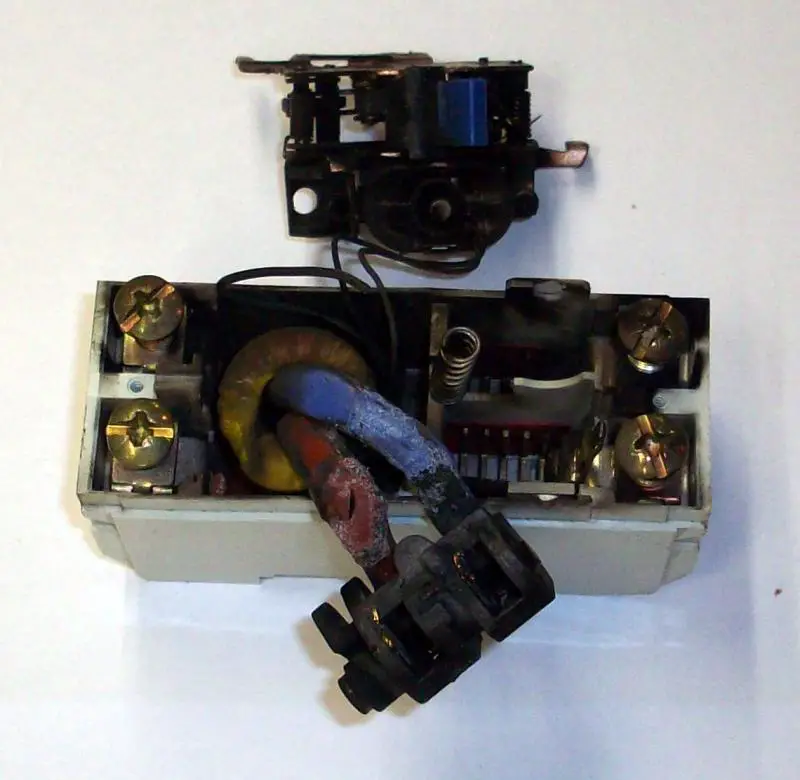

As I said, that's certainly what I would have expected....looking at the circuit diagrams it would seem that the test button circuit is on the load side of the RCCB so would only be energised until the breaker trips. ...

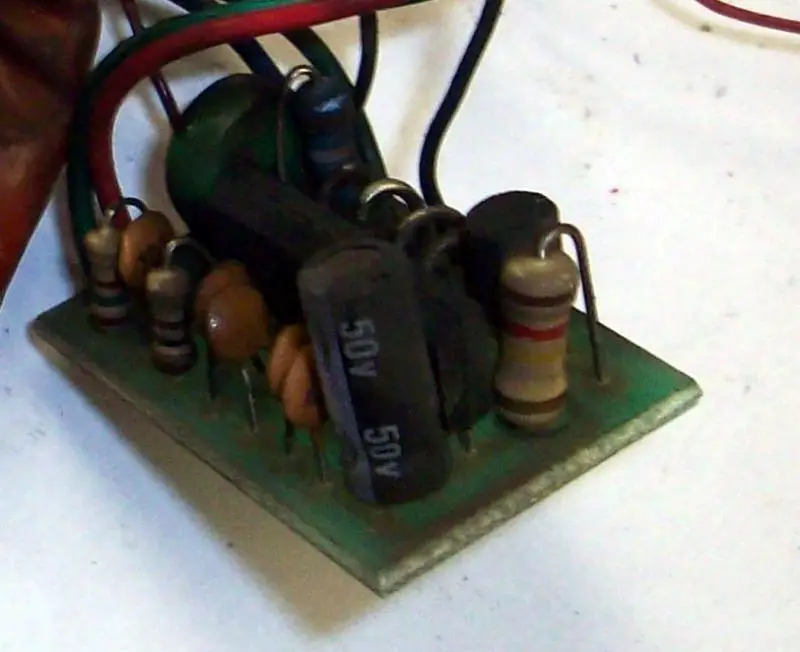

She appears to be reporting that the bang happened the moment she touched the button - but that could obvioulsy mean anything from a few mS to a few hundred.Assuming it tripped in the proper time this, presumably, would not cause overheating but if the device were faulty how long did it really take?

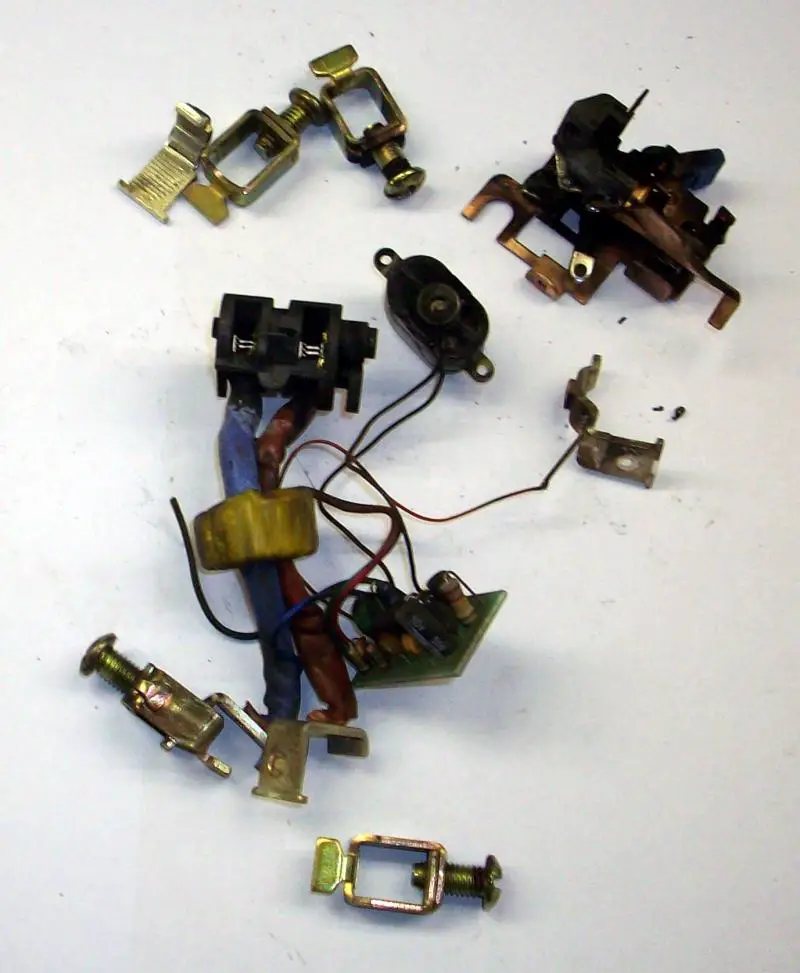

As you say, very much less than satisfactory I would say. I'm sure one wouldn't have to keep one's finger on the button for long to fry the resistor.Also, I have read many threads about the wiring of RCDs and I think it is accepted that wiring the other way round, i.e. supply to the bottom does not matter but this would then mean the test button circuit would be on the supply side causing the current to flow until the button was released. Either way, if that were the cause, it does seem to be less than satisfactory.

Kind Regards, John