Yes not fighting, tony challenges gentlemen to a duel!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Splice beams

- Thread starter Brutus76

- Start date

Sponsored Links

This is good work Fubar. Have a gold starHaving recently learned some basic structural calcs, I'll give you the hows and whys before the whats.

A beam (lintel, joist, scaffold plank, floor board... etc) has a property called 'Second Moment Of Inertia' which is that beams shape and sizes ability to resist bending. The unit for SMOI is given as mm^4 and for a square / rectangular beam is given as:

(W x (H^3)) / 12.

As you can see from that, if you double the width (such as bolting 2 joists together), you double the SMOI. If you double the height, you increase the SMOI by 8.

Once you have a beams SMOI, you can calculate the maximum center deflection by using the calcs on this website:

http://www.engineeringtoolbox.com/beam-stress-deflection-d_1312.html

The 'Youngs Modulus' or 'Modulus of elasticity' for steel and C16 (structural) timber are around:

Timber: 6,000N/mm^2

Steel: 200,000N/mm^2

As you can see, and as makes sense, Steel is much stronger than timber.

If you sandwedge a 6mm piece of steel between 2x 220x47. You get the equivalent deflection figures as a:

47+47+((200000/6000) x 6) = 47+47+200 = 220x294

So with minimum increase in overall size of the joist, you make it over 3 times stronger.

Alternatively, if you run the maths for a piece of I beam steel or box section steel (that you could fit between the joists) using these calcs for SMOI:

http://civilengineer.webinfolist.com/str/micalc.htm

you may find you can get away with installing steels between the existing joists.

So, really, your options would be:

1) Sister the joists up with steel between them (there is a fancy word for them that escapes me.

2) Install a steel beam across the room to split it into 2x 3m spans.

3) Install additional steel beams (probably I beams) between the existing joists for the whole span

Of all of these, 3 would probably be the easiest, but even then, 6m is a damn big span and this is going to be a BIG job regardless of how you go about it.

Unless you have the money to spend, I would consider keeping a pillar next to where the door is and the horizontal beam.

As to what the wife says. I tell mine "you are in charge of how it looks, but I am in charge of how it's build". It's better to have a slightly ugly room than a pretty pile of rubble.

!!!PLEASE NOTE!!!!

I am not a structural engineer.

I'm supplying this information for informative purposes only so you understand the situation.

There WILL be other factors to consider.

Please get a structural engineer in because this is a prime opportunity for massive structural failure. This may seem hypocritical considering my current project, but worst case if mine fails, the roof will bow and leak. Worst case for you, the house could come down.

Fubar.

With reference to the flitch beam design, idealy the steel and the timber should be designed to deflect by the same amount, otherwise either the timber or steel will be more highly stressed.

In order to do that, you have to ensure that the EI value is the same.

So, taking your pair of 220x47s with a Young's Modulus of 6000N/mm2 as a starting point the EI value is 5^11

So we now need to find a steel plate with the same EI value.

5^11 / 200000 = I = 2502280mm^4

So required thickness "b" = 12 I / d^3

So, assuming the plate is 220mm deep, b = (12 * 2502280) / 220^3 = 2.82mm, so you should use a 3mm plate.

Of course that's not as strong as using a thicker plate, and what people often do is completely ignore the timber in the calculation and just rely on the steel.

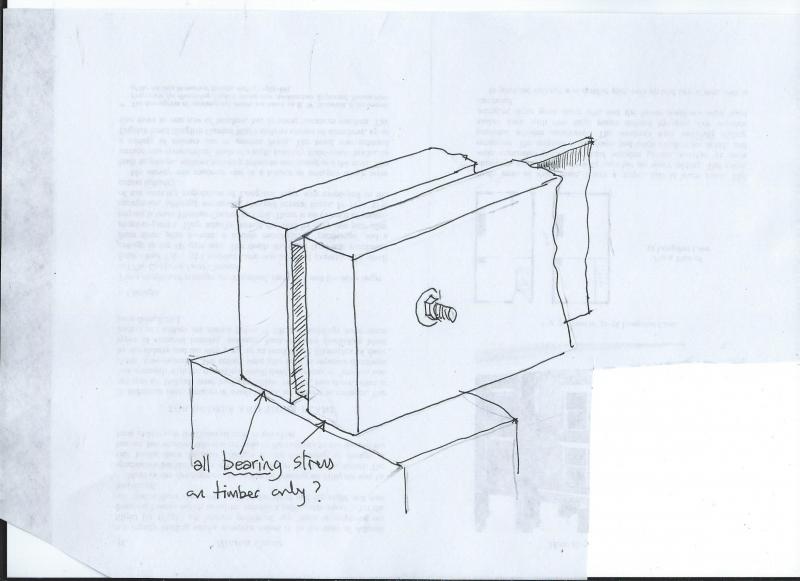

Also, it's usual to make the steel slightly less deep than the timber so that the timber takes all of the bearing stresses, which should be transferred to the timber by the bolts.

And so ends tonight's lesson. Please do your homework; I will be testing you tomorrow

Let me know if you spot any more mistakes in my calcs...it's getting late

Don't you mean transferred to the steel through the bolts?

If 'Woody' comes and joins in now, there'll be no gold stars, it'll be detention for you and me Ronny.

Sponsored Links

Yes, well spottedDon't you mean transferred to the steel through the bolts?

Actually Ronny, I think you were right first time. You said 'bearing stress' and if the steel is shallower than the timber, the timber will take all the bearing force. And that force is of course transferred from steel to timber via the bolts.

Or were you perhaps absent-mindedly intending to say bending stress?

Or were you perhaps absent-mindedly intending to say bending stress?

Well Brutus, despite the fighting (which I'm sure is more like friendly sparing). You have 3 very knowledgeable gents commenting on your problem (and that's not including me because I know peanuts).

Glad you got the SE in and as I would expect, steel is needed.

From a cosmetic stand point. Do you know what sort of decorating style the missus is after? It may be possible to disguise the steel as a feature item, from cladding it in oak or stone for a classical appearance to using it as a mount for feature lighting for a more modern look.

(also, cheers for clearing up on the ^4 vs ^3 issue Tony, hadn't factored in the additional L value in the pressure - force translation. As to picking it up faster, I have google, and random people on the internet to tell me when I mess up

Ronny, from what you say, I need to look into the impact of stress issues. Will have a read when time allows. Not that I need to know, but now I'm curious and experiments to failure are always fun ... just not on your own house)

... just not on your own house)

Fubar.

Glad you got the SE in and as I would expect, steel is needed.

From a cosmetic stand point. Do you know what sort of decorating style the missus is after? It may be possible to disguise the steel as a feature item, from cladding it in oak or stone for a classical appearance to using it as a mount for feature lighting for a more modern look.

(also, cheers for clearing up on the ^4 vs ^3 issue Tony, hadn't factored in the additional L value in the pressure - force translation. As to picking it up faster, I have google, and random people on the internet to tell me when I mess up

Ronny, from what you say, I need to look into the impact of stress issues. Will have a read when time allows. Not that I need to know, but now I'm curious and experiments to failure are always fun

Fubar.

Erm...steel takes the bending and shear stresses, timber takes the bearing stresses.Actually Ronny, I think you were right first time. You said 'bearing stress' and if the steel is shallower than the timber, the timber will take all the bearing force. And that force is of course transferred from steel to timber via the bolts.

Or were you perhaps absent-mindedly intending to say bending stress?

So, where the steel is designed to take the full load:

The bending stresses are all taken by the steel...

The shear stresses are transferred from the steel to the timber at the bearings through the bolts...

And likewise, the bearing stresses are transferred from the timber to the steel through the bolts...

So that means Catlad was right, doesn't it?

Or maybe it works both ways

You lot are just to technical one component will not work without the other, so it don't really matter does it. Anyway I was only teasing.

Hah..being a farmer boy from Norway I thought I could diy a little and surely fix a little roof, but from your answers I can see there can be quite a little more to beams and joists!

To answer the question of what style the missus prefers..well, she basically sees a few pictures of nice open plan spaces with no beams etc on houzz and tells me just to fix it like that since it 'looks easy enough'.. To be realistic though, today we'll find the design, get a beam and get to work. I'll upload a picture of the finished room afterwards just fyi.

again thanks

To answer the question of what style the missus prefers..well, she basically sees a few pictures of nice open plan spaces with no beams etc on houzz and tells me just to fix it like that since it 'looks easy enough'.. To be realistic though, today we'll find the design, get a beam and get to work. I'll upload a picture of the finished room afterwards just fyi.

again thanks

So the timber takes all the bearing stresses - at both the supports and along its length from whatever it is supporting.Re the bearing stress on the spliced beam;

FWIW, this is may take on the position;

If the steel plate is shallower (top-to-bottom) than the timber beams, then surely only the timber is in contact with the padstone, so logically all the bearing stress must be on the timber?

All of these bearing stresses along the beam's length are transferred as a shear force through the bolts to the steel.

The steel then resists bending along its length, and shear at its end.

The shear force is then transferred through the bolts as a shear force into the timber, which then transfers the load to the bearing in the form of a bearing stress. Right?

Never really thought about it in detail before

Brutus, it's not impossible to hide the beam in the depth of the ceiling. Although it would mean a lot more work requiring a lot of cutting and resupporting of the joists.Hah..being a farmer boy from Norway I thought I could diy a little and surely fix a little roof, but from your answers I can see there can be quite a little more to beams and joists!

To answer the question of what style the missus prefers..well, she basically sees a few pictures of nice open plan spaces with no beams etc on houzz and tells me just to fix it like that since it 'looks easy enough'.. To be realistic though, today we'll find the design, get a beam and get to work. I'll upload a picture of the finished room afterwards just fyi.

again thanks

Many moons ago, I was taught that joists should be span(feet)/thickness(inches) + 2 (inches). Obviously this has little relevance to matey's knock through which should really be supported by something manlike.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links