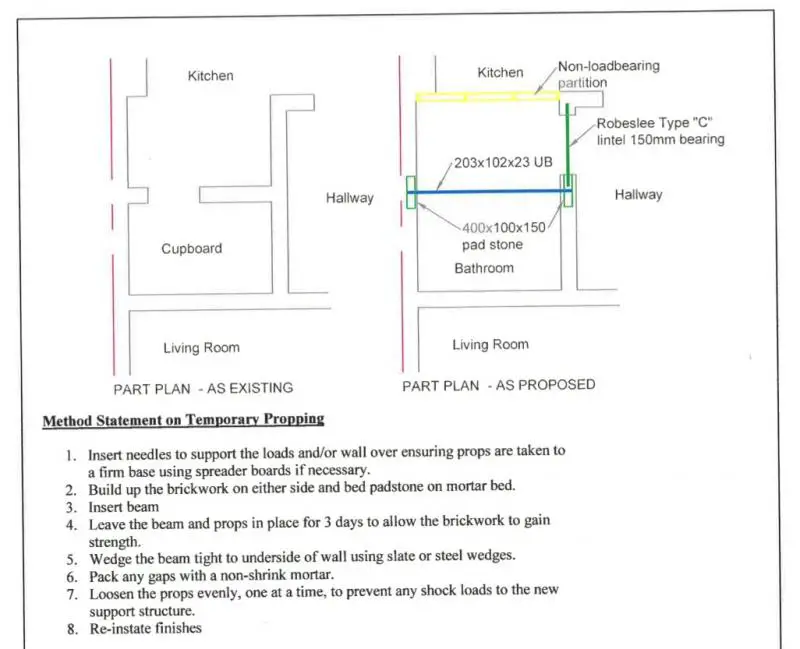

I am wondering what I should do and whether my builder's work has any chance of meeting the building regs. We are in a 4 story tenement with a concrete tile roof. We wanted a structural wall removed and a new doorway opened. The engineers drawing had the steel beam and the concrete lintel at right angles to each other, with the lintel to the right of the steel beam, both sitting on the the brick wall in which the new door way is locate. It sounds complicated but you will get the idea from the pictures.

The builder's first attempt seemed to have the new door opening too far to the left. The steel beam, holding up the floors above, was resting on the lintel with nothing but fresh air beneath. This did not look right to me and I complained that it did not match the engineer's drawing. His next attempt placed the steel beam on top of the lintel which is now supported on a vertical stack of bricks, which he says are tied into the wall. However, it still does not match the engineer's drawing, which has the lintel to the right of the steel beam.

I am also a bit concerned that the new door opening is supported by a single prop which is way off to the side. We were planning to send photos of the work in progress to the council so that they could approve it without coming out to inspect.

Will this pass building regs?

What should I do?

I am a bit afraid of what will happen when he removes the props.

The builder's first attempt seemed to have the new door opening too far to the left. The steel beam, holding up the floors above, was resting on the lintel with nothing but fresh air beneath. This did not look right to me and I complained that it did not match the engineer's drawing. His next attempt placed the steel beam on top of the lintel which is now supported on a vertical stack of bricks, which he says are tied into the wall. However, it still does not match the engineer's drawing, which has the lintel to the right of the steel beam.

I am also a bit concerned that the new door opening is supported by a single prop which is way off to the side. We were planning to send photos of the work in progress to the council so that they could approve it without coming out to inspect.

Will this pass building regs?

What should I do?

I am a bit afraid of what will happen when he removes the props.