- Joined

- 4 Jan 2020

- Messages

- 28

- Reaction score

- 0

- Country

Hi All

It is always great to post things here as everyone is willing to help. My UFH got installed 1 year ago and it does not get heated properly.

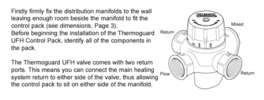

I notice pipes connected to blue are hot and pipes in red are warm so not sure if engineer has connected pipes properly. I am also not sure on the pressure of each valve.

Please suggest if connecs are correct and also if both pipes are not equally hot also how to bleed the system

Video link

It is always great to post things here as everyone is willing to help. My UFH got installed 1 year ago and it does not get heated properly.

I notice pipes connected to blue are hot and pipes in red are warm so not sure if engineer has connected pipes properly. I am also not sure on the pressure of each valve.

Please suggest if connecs are correct and also if both pipes are not equally hot also how to bleed the system

Video link