Hey everyone, I am new to the forum so first of all I would like to say Thank You if you are reading this. Secondly I would like to share the difficulties I am having with my project.

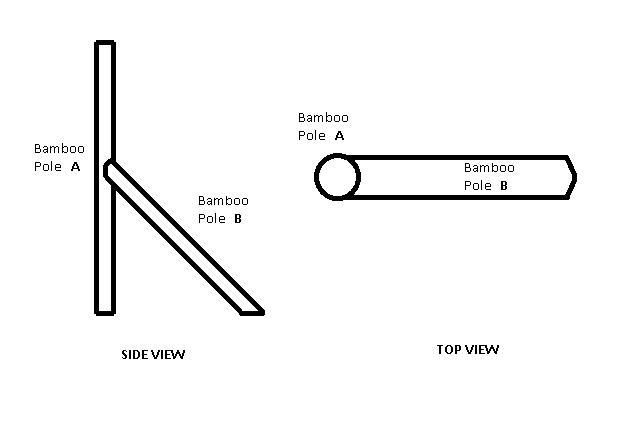

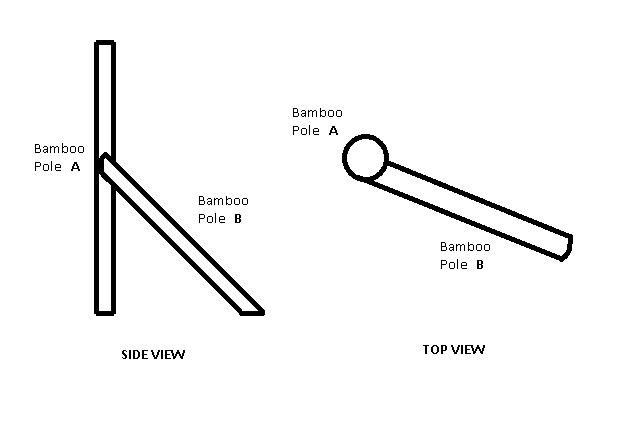

For the last few days I have been trying to make unique sculptures out of Bamboo and to step up the game I was hoping to use bamboo meeting each other at "funny angles" rather than right angles.

Now at first I thought I could mitre my poles using a dremel but I soon realised how hard and imperfect this method is, so I got myself a Drill Press. This particular drill press goes up to 2650 rpm max and comes with a tilting table. I know there are other drill presses out there but this is what I could afford at the moment.

Next I realised I would need a vice to go on the tilting table so I got myself this Vice. Now this vice can be bolted onto the tilting table but only at certain points as the tilting table has a limited space where the vice could be bolted on.

The tilting table doesn't come with any angle markings so I got myself a Protractor. I choose this protractor because of the movable marker on it.

I have all these little bits with me now and I know what I want to achieve but I am not really not sure how to do it. What I want is to mitre bamboo poles using holesaws at various angles and at various offsets.

The idea that I have in my head is to first construct a base for the vice which connects to the tilting. This base can move in both x and y direction allowing me to drill holes at offset distances from the centre. Secondly I would like to use the protractor on the tilting table in such a way so that the angles could be read perfectly (not really sure where to begin with that). Lastly I was thinking of making a laser cross hair for the drill press so that the offset from the centre could be read perfectly.

Not sure if you guys could understand my rough explanation but I was hoping to get some ideas as what shall I do to get this desired platform for mitering. If you think this explanation is crap or the post is irrelevent to this forum then please let me know. Cheers

For the last few days I have been trying to make unique sculptures out of Bamboo and to step up the game I was hoping to use bamboo meeting each other at "funny angles" rather than right angles.

Now at first I thought I could mitre my poles using a dremel but I soon realised how hard and imperfect this method is, so I got myself a Drill Press. This particular drill press goes up to 2650 rpm max and comes with a tilting table. I know there are other drill presses out there but this is what I could afford at the moment.

Next I realised I would need a vice to go on the tilting table so I got myself this Vice. Now this vice can be bolted onto the tilting table but only at certain points as the tilting table has a limited space where the vice could be bolted on.

The tilting table doesn't come with any angle markings so I got myself a Protractor. I choose this protractor because of the movable marker on it.

I have all these little bits with me now and I know what I want to achieve but I am not really not sure how to do it. What I want is to mitre bamboo poles using holesaws at various angles and at various offsets.

The idea that I have in my head is to first construct a base for the vice which connects to the tilting. This base can move in both x and y direction allowing me to drill holes at offset distances from the centre. Secondly I would like to use the protractor on the tilting table in such a way so that the angles could be read perfectly (not really sure where to begin with that). Lastly I was thinking of making a laser cross hair for the drill press so that the offset from the centre could be read perfectly.

Not sure if you guys could understand my rough explanation but I was hoping to get some ideas as what shall I do to get this desired platform for mitering. If you think this explanation is crap or the post is irrelevent to this forum then please let me know. Cheers