Good Morning

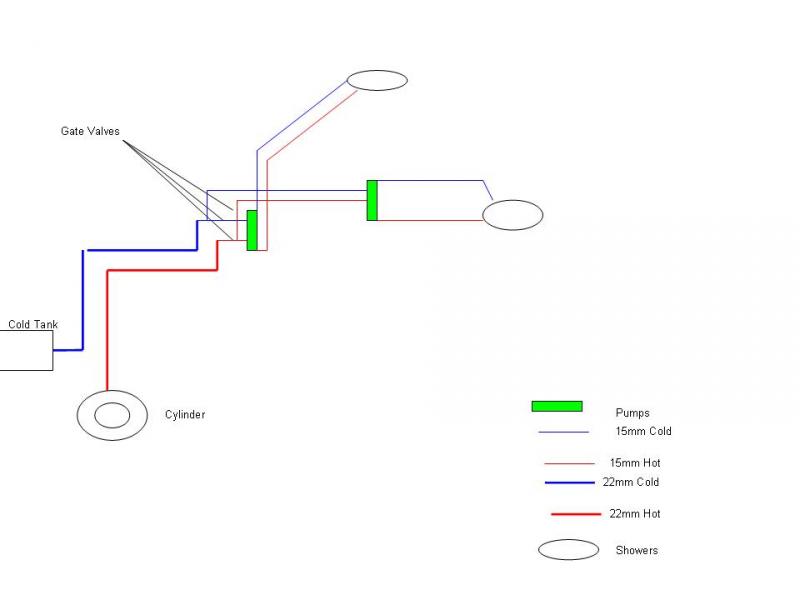

My system is gravity fed and everything is in the loft (headers, cylinder etc.) I have just had a new 22mm feed fed to my new bath, a 22mm feed fed towards my first shower which reduces to 15mm prior to a salamander 1.5 bar pump, the 15mm pipes are then split to feed a second salamander 1.5 bar pump for shower 2.

Since having an upgrade to 22mm towards the showers the pressure flow in shower 1 is worse than before and temperature fluctuates which has never happened before. (Problem 1)

Problem 2 is that due to the tap in the new bathroom being a 15mm inlet fed ceramic disc type (not sure what I'm on about here but am quoting information from another source) this needs to be pressure fed.

So to summarise, what is the best approach if I started from scratch to feed 2 showers (negative head) and increase the pressure to the bath. It is not an option to change the tap at present so need to conside what pump options I have and if I need a Surrey Flange or similar fitting.

I know this is a long topic but hopefully we can break it down into stages. This is seriously beginning to damage my health

Thanks in advance - Rhys

My system is gravity fed and everything is in the loft (headers, cylinder etc.) I have just had a new 22mm feed fed to my new bath, a 22mm feed fed towards my first shower which reduces to 15mm prior to a salamander 1.5 bar pump, the 15mm pipes are then split to feed a second salamander 1.5 bar pump for shower 2.

Since having an upgrade to 22mm towards the showers the pressure flow in shower 1 is worse than before and temperature fluctuates which has never happened before. (Problem 1)

Problem 2 is that due to the tap in the new bathroom being a 15mm inlet fed ceramic disc type (not sure what I'm on about here but am quoting information from another source) this needs to be pressure fed.

So to summarise, what is the best approach if I started from scratch to feed 2 showers (negative head) and increase the pressure to the bath. It is not an option to change the tap at present so need to conside what pump options I have and if I need a Surrey Flange or similar fitting.

I know this is a long topic but hopefully we can break it down into stages. This is seriously beginning to damage my health

Thanks in advance - Rhys