Hi,

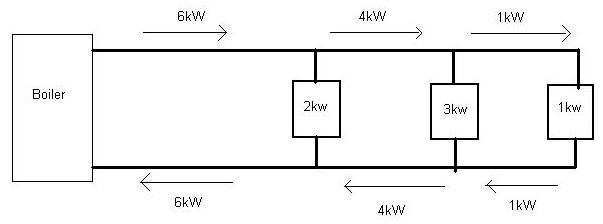

We have just installed 3 extra radiators onto a branch of the heating circuit that is run off a 15mm pipe. This used to have just one rad on it.

These rads are not getting as hot as the rest of the house (even after balancing).

I've just read on this forum that a rule of thumb is 4kW max for a 15mm pipe, and indeed this the case - the combined total is more like 6kW.

My plumber has advised we can increase the pipe to 22mm for most of the circuit and this would help. By most I mean the bits in the loft and bits that come down some boxing, but it would still leave about 20% at 15mm that is in-cased in the wall.

So - is this actually true. Would increasing approximately 70-80% of the feed improve the situation, bearing in mind there will still be a 'bottleneck' in the pipe.

I'm assuming it would have some benefit (less overall resistance etc.), but I also concerned it may cause other problems - i.e. introducing noise as the flow rate (?) increases in remaining 15mm section.

Hope that makes sense as a question.

Steve

We have just installed 3 extra radiators onto a branch of the heating circuit that is run off a 15mm pipe. This used to have just one rad on it.

These rads are not getting as hot as the rest of the house (even after balancing).

I've just read on this forum that a rule of thumb is 4kW max for a 15mm pipe, and indeed this the case - the combined total is more like 6kW.

My plumber has advised we can increase the pipe to 22mm for most of the circuit and this would help. By most I mean the bits in the loft and bits that come down some boxing, but it would still leave about 20% at 15mm that is in-cased in the wall.

So - is this actually true. Would increasing approximately 70-80% of the feed improve the situation, bearing in mind there will still be a 'bottleneck' in the pipe.

I'm assuming it would have some benefit (less overall resistance etc.), but I also concerned it may cause other problems - i.e. introducing noise as the flow rate (?) increases in remaining 15mm section.

Hope that makes sense as a question.

Steve