that's a 3 phase motor converted to run on single phase

so yes possibly the cap

any chance of a pic of the terminals?

Matt

Hi Matt,

Yes I have some here.

Thanks

that's a 3 phase motor converted to run on single phase

so yes possibly the cap

any chance of a pic of the terminals?

Matt

No probs and the cap will cost you around £7 from RS components hereAll I have is 240v here.

I will dig out my tester and have a look and get a new capacitor as I don't think they cost that much.

Thanks Matt

No probs and the cap will cost you around £7 from RS components hereAll I have is 240v here.

I will dig out my tester and have a look and get a new capacitor as I don't think they cost that much.

Thanks Matt

Make sure you get one designed for continuous duty (running not starting)

Matt

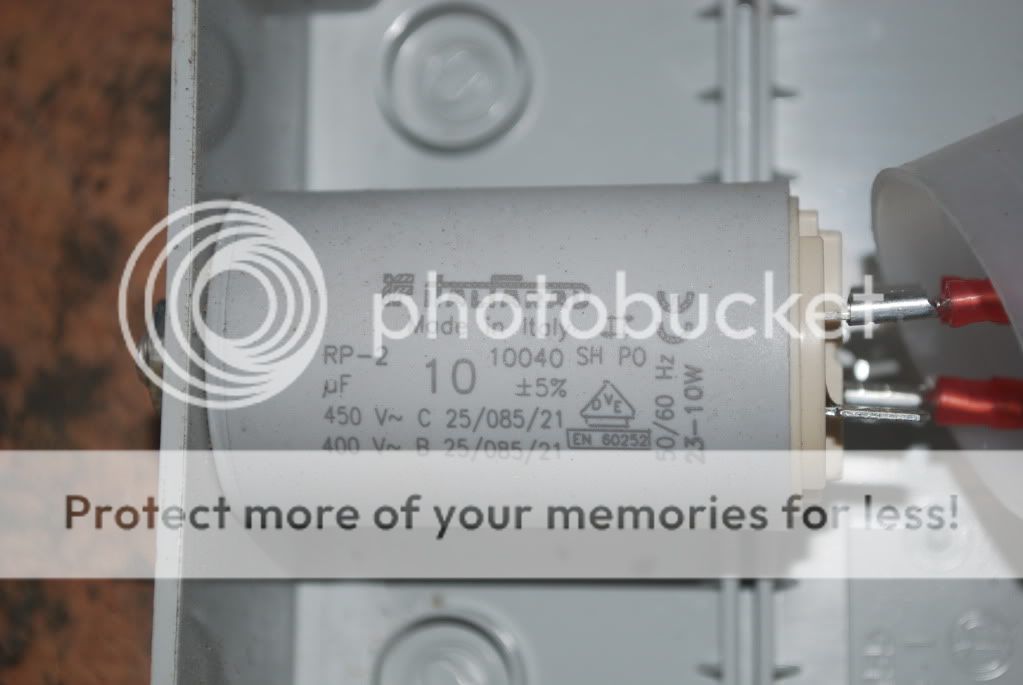

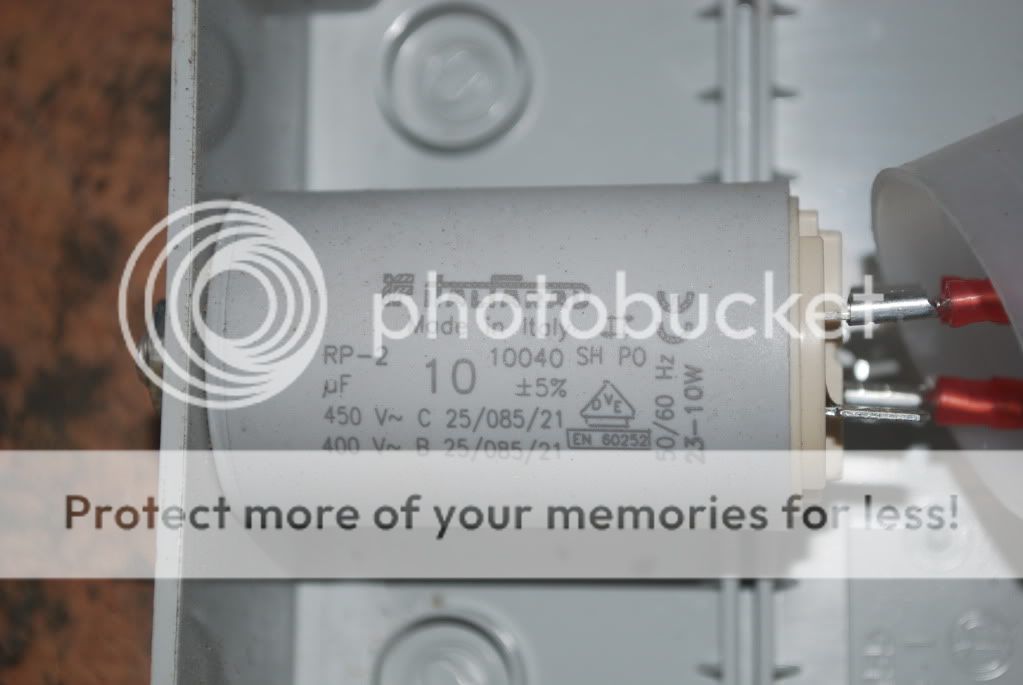

As I said in my earlier post, did you check that bothe weights are in the same plane i.e. downwards, as i can see the front one is hanging at the bottom, like wise make sure the one at the other end is in the same angle, if one rotates as I can see if the nut gets loose it can slide off its intened angle, as for capacitance, I do know some central heating water pumps stop running fast when a cap goes down, they spin so slow, and most I came across use 2.2uF 400Volts, they are roughly the size of a C size battery, you could try to undo the compartment where the cap is mounted and the value will be printed on it with the voltage rating. I am guessing for a motor this size you will probably need a higher capacitance possibly up to 10uF 400Volts and thats going to be fairly large like a D size cell.

That motor is dual wound. This means it is designed to run either at 400V in star or 230V in delta.

variable speed drive

t if the cap dosn't sort it I will have a mess with the weights.

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Are you a trade or supplier? You can create your listing free at DIYnot Local