While hunting down the cause of corrosion in our open vent system I found that we have some 'pumping over' going on. It does not happen all the time but can be made to happen continuously if the pump is set on its highest speed. Normally we only run the pump on its medium setting but even then it seems to occur occasionally.

To test this I put a small plastic tub inside the F&E tank below the vent. When I checked it this moring, it was full.

When the pump on full speed a constant stream of water is produced at the vent.

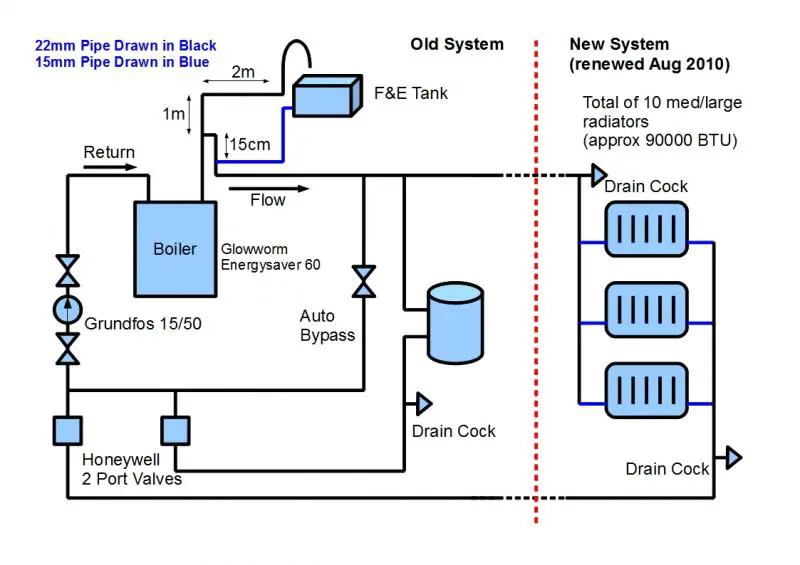

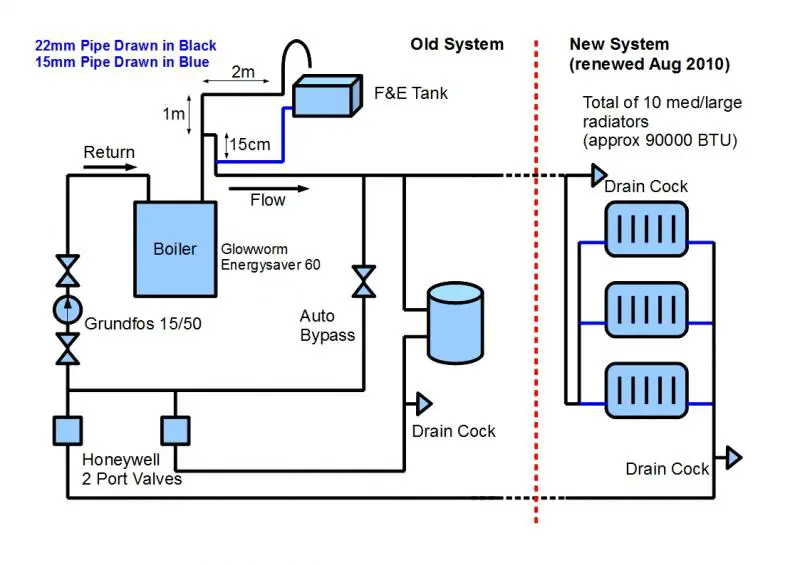

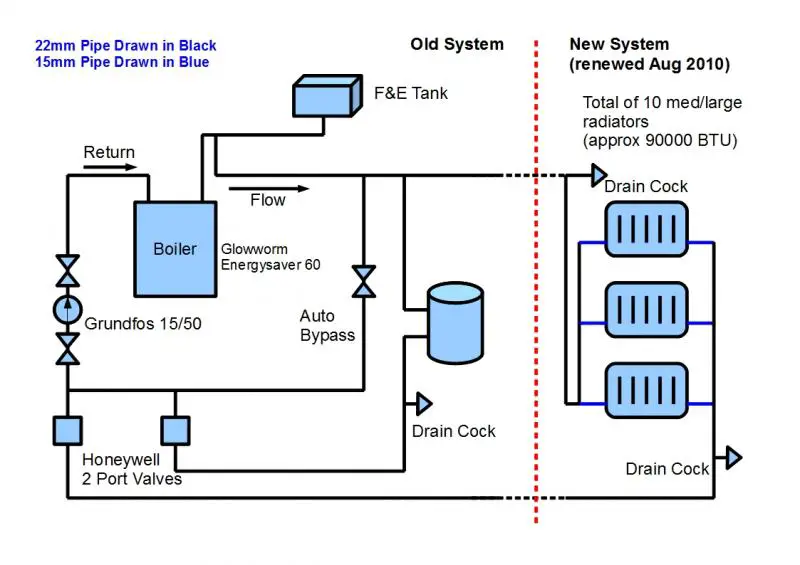

Below is a diagram of our system including a few measurements of the pipework around the F&E tank.

Can anyone suggest why the pumping over might be occuring?

Cheers,

iep

To test this I put a small plastic tub inside the F&E tank below the vent. When I checked it this moring, it was full.

When the pump on full speed a constant stream of water is produced at the vent.

Below is a diagram of our system including a few measurements of the pipework around the F&E tank.

Can anyone suggest why the pumping over might be occuring?

Cheers,

iep