Hi,

I have a bit of strange request and need some help wiring up a water heater thermostat to switch off a light bulb when it gets to a certain temperature as it's being used in a enclosed incubator.

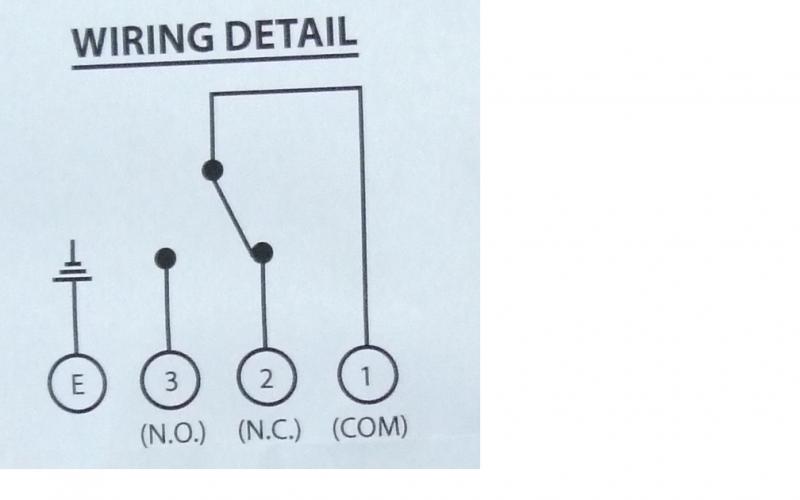

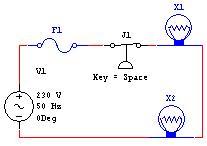

I've included the wiring diagram of the Danfoss ATC thermostat which civers the temperature range I require and the wiring diagram, I need to connect this up to a regular light bulb. I need the thermostat to cut in and switch the light bulb off when the temperature rises above a set temperature and then to switch back on when the temperature drops.

Any help would be greatly appreciated.

Thermostat

Wiring Diag

Here is a link to the actual thermostat

http://www.screwfix.com/prods/61083/Plumbing/Central-Heating-Controls/Danfoss-ATC-Cylinder-Stat

I have a bit of strange request and need some help wiring up a water heater thermostat to switch off a light bulb when it gets to a certain temperature as it's being used in a enclosed incubator.

I've included the wiring diagram of the Danfoss ATC thermostat which civers the temperature range I require and the wiring diagram, I need to connect this up to a regular light bulb. I need the thermostat to cut in and switch the light bulb off when the temperature rises above a set temperature and then to switch back on when the temperature drops.

Any help would be greatly appreciated.

Thermostat

Wiring Diag

Here is a link to the actual thermostat

http://www.screwfix.com/prods/61083/Plumbing/Central-Heating-Controls/Danfoss-ATC-Cylinder-Stat