Hello from a fresh newcomer.

I am preparing to convert the garage that is attached to my house into a private recording studio.

In brief, this will entail building a decoupled room inside the existing shell, but without going into those details, the big problem I have is that the existing garage roof is simply corrugated plastic sheets fitted above the joists --- and these are "flashed" into the pebbledashed wall where the garage meets the house.

It would take some time for me to go through all of the details relating to the build requirements for a studio environment, but once completed, I would essentially have a double layer of 5/8" Gypsum as a ceiling, about 4" of rockwool insulation above that, then at least a double layer of 18mm OSB.

There may be a small air gap between the rockwool and the underside of the OSB, but I cannot ventilate this space as I need to seal every possible gap and make it as airtight as possible (in theory).

I therefore need to build a warm roof and having researched as much as possible, I have been advised to fit a minimum of 150mm of Kingspan above the OSB decking to avoid condensation.

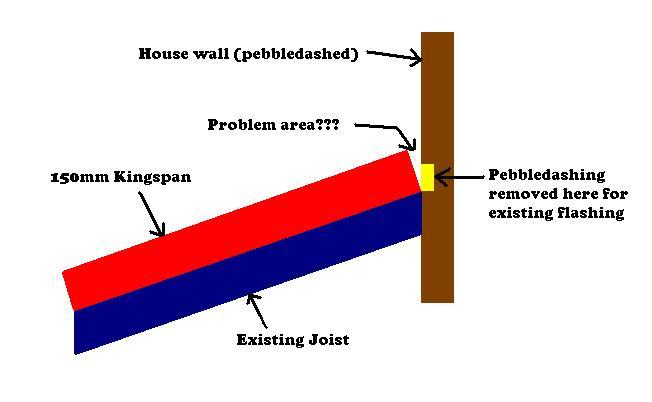

If I lay 150mm of Kingspan as well as 2 x 18mm OSB on top of the joists, then I will be faced with two problems.

Firstly, there will be a natural angle caused by the slight pitch of the roof where the Kingspan meets the house (see diagram) and the uppermost surface that would need to be waterproofed would end up above the strip on the house wall that is already stripped and chased of the pebbledashing (this strip is where the current flashing for the plastic roof is attached to the wall).

I am loathe to have to chase a new strip further up the wall, so am wondering if anyone has any ideas for these two issues?

Many thanks.

Steve

I am preparing to convert the garage that is attached to my house into a private recording studio.

In brief, this will entail building a decoupled room inside the existing shell, but without going into those details, the big problem I have is that the existing garage roof is simply corrugated plastic sheets fitted above the joists --- and these are "flashed" into the pebbledashed wall where the garage meets the house.

It would take some time for me to go through all of the details relating to the build requirements for a studio environment, but once completed, I would essentially have a double layer of 5/8" Gypsum as a ceiling, about 4" of rockwool insulation above that, then at least a double layer of 18mm OSB.

There may be a small air gap between the rockwool and the underside of the OSB, but I cannot ventilate this space as I need to seal every possible gap and make it as airtight as possible (in theory).

I therefore need to build a warm roof and having researched as much as possible, I have been advised to fit a minimum of 150mm of Kingspan above the OSB decking to avoid condensation.

If I lay 150mm of Kingspan as well as 2 x 18mm OSB on top of the joists, then I will be faced with two problems.

Firstly, there will be a natural angle caused by the slight pitch of the roof where the Kingspan meets the house (see diagram) and the uppermost surface that would need to be waterproofed would end up above the strip on the house wall that is already stripped and chased of the pebbledashing (this strip is where the current flashing for the plastic roof is attached to the wall).

I am loathe to have to chase a new strip further up the wall, so am wondering if anyone has any ideas for these two issues?

Many thanks.

Steve