Hi, I'm not a plumber, but I'm fairly knowledgeable and confident with domestic plumbing. Currently, I have a 24kw worcester greenstar conventional boiler that feeds the existing radiators, underfloor heating and old vented copper 900x450 cylinder which is fully insulated.

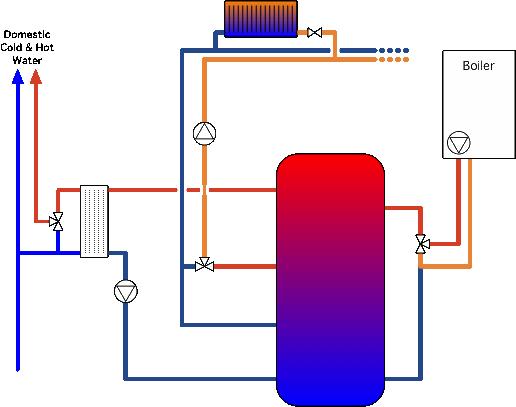

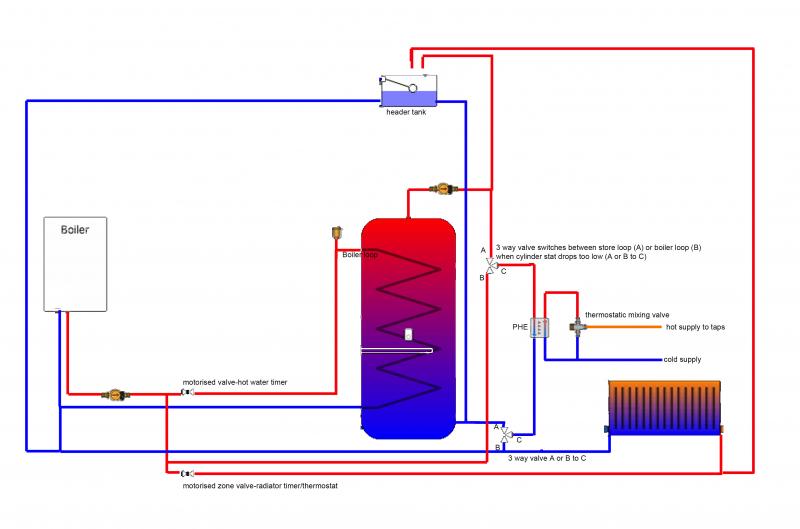

I want to get rid of the cold storage tank in the loft, and the shower pump that supplies DHW to the showers, kitchen spray tap e.t.c. and was wondering if it would be possible to use the existing cylinder as a thermal store, and install a plate heat exchanger like this: http://heatweb.com/solar/schemat.GIF )

This would be the cheapest option The house is big and we have 2 bathrooms. My question is, can you simply turn up the cylinder stat to 80 degrees, fit a flow switch and use the existing tank as a thermal store loop with the heat exchanger? Do you think the capacity would be high enough, and is the coil smaller than a modern thermal store (recovery time fast enough?--at the moment, the hot water runs out just as the bath is almost full, but the cylinder is only set to 55 degrees)

The radiators/underfloor heating are not pressurised (there is a small expansion tank in the loft)-Can I leave it this way, and use the same expansion tank as a filler for the cylinder exchanger loop also?

Thanks, I simplified this, apologies for the wordiness, would really appreciate any thoughts

I want to get rid of the cold storage tank in the loft, and the shower pump that supplies DHW to the showers, kitchen spray tap e.t.c. and was wondering if it would be possible to use the existing cylinder as a thermal store, and install a plate heat exchanger like this: http://heatweb.com/solar/schemat.GIF )

This would be the cheapest option The house is big and we have 2 bathrooms. My question is, can you simply turn up the cylinder stat to 80 degrees, fit a flow switch and use the existing tank as a thermal store loop with the heat exchanger? Do you think the capacity would be high enough, and is the coil smaller than a modern thermal store (recovery time fast enough?--at the moment, the hot water runs out just as the bath is almost full, but the cylinder is only set to 55 degrees)

The radiators/underfloor heating are not pressurised (there is a small expansion tank in the loft)-Can I leave it this way, and use the same expansion tank as a filler for the cylinder exchanger loop also?

Thanks, I simplified this, apologies for the wordiness, would really appreciate any thoughts