The central heating is original from when the property was built and, as the setup is Primatic, has never had or been able to have inhibitor. Only on 2nd boiler since new and I'd be very surprised if the system has been flushed at any time except for the boiler replacement, if that. Now intending to replace the current boiler and get rid of the Primatic so the system can have inhibitor. But should all the pipework be replaced at the same time? If not, what sort of lifetime should I expect post system update (ie new boiler, Primatic changed to something decent, inhibitor added and kept up to date)?

I did the corrosion test of 2 jars containing an iron nail and copper coin, one with circuit water and one with fresh from the tap water and am attaching photos. The nails were as new as I had to hand, bright with no corrosion visible. Both nails corroded but the circuit water nail corroded MUCH faster than the tap water nail and also turned the water rust coloured. I also tried checking pH with some litmus paper I had to hand but that didn't help. Finally, according to the water provider the water here is 130 mg/l / 9.24 Clarke degree (moderate hard).

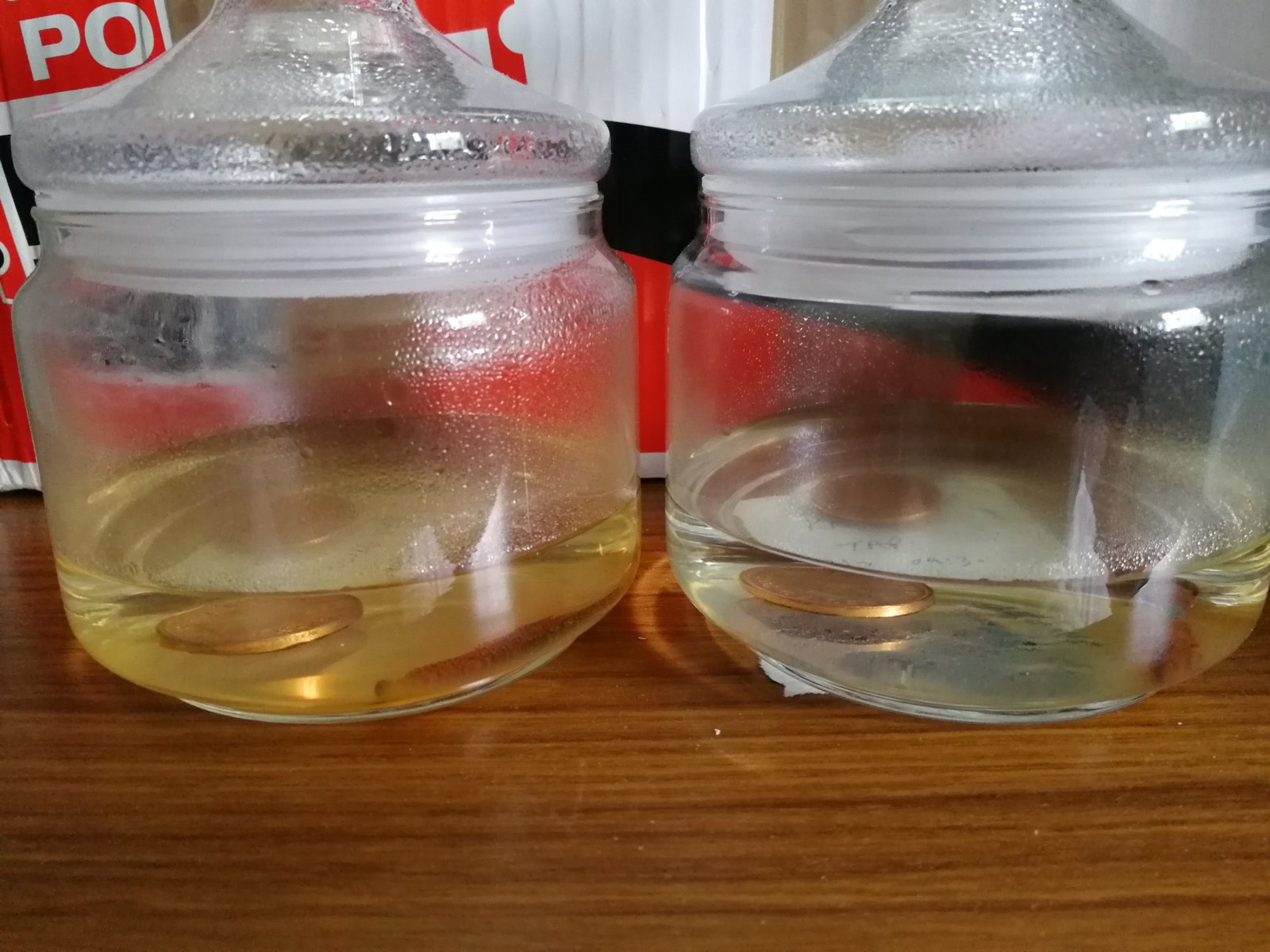

Here is both jars, after 1 day. Circuit water on left, tap water on right.

Here are close ups of circuit (first) and tap (second)

Then after days here are both jars again

And here are close ups of circuit (first) and tap (second)

I did the corrosion test of 2 jars containing an iron nail and copper coin, one with circuit water and one with fresh from the tap water and am attaching photos. The nails were as new as I had to hand, bright with no corrosion visible. Both nails corroded but the circuit water nail corroded MUCH faster than the tap water nail and also turned the water rust coloured. I also tried checking pH with some litmus paper I had to hand but that didn't help. Finally, according to the water provider the water here is 130 mg/l / 9.24 Clarke degree (moderate hard).

Here is both jars, after 1 day. Circuit water on left, tap water on right.

Here are close ups of circuit (first) and tap (second)

Then after days here are both jars again

And here are close ups of circuit (first) and tap (second)