- Joined

- 5 Apr 2006

- Messages

- 131

- Reaction score

- 0

- Country

Hi all

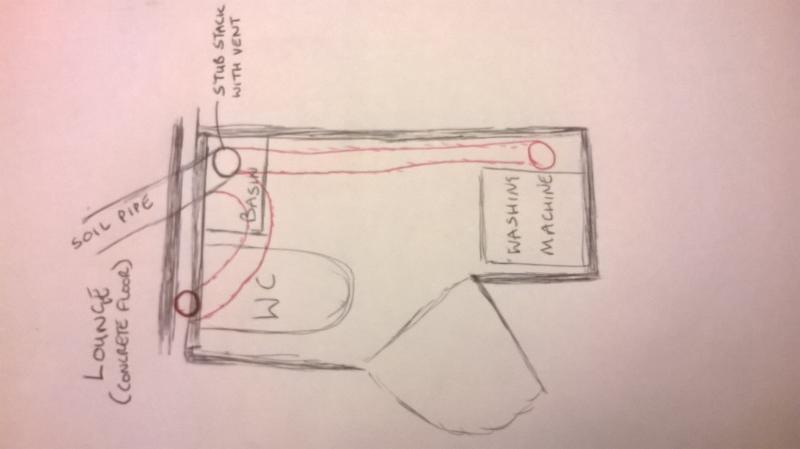

I'm looking for some advice when replumbing my (ground floor) cloakroom. The room is very limited for space and was part of a larger extension. In the end the builder left the cloakroom unfinished, for various reasons. I am now ripping the existing T+G floor up to put down a plywood base for tiles and am sorting out the drainage.

I have included a sketch of the current layout (which could change if needed) in black. The soil pipe currently enters the cloak room below floor level through a double skinned brick wall (that used to be the exterior wall before the extension). The other side of that wall is our lounge which has a concrete floor. The builders put in a stub stack with an osmavent underneath the basin. The WC has a hidden cistern inside the cavity, which will have a coloured glass panel to hide it (as well as providing a sanitary "splash back" for the WC). Currently everything is connected into the stub stack above floor level to maintain minimum distance above the invert.

The particularly bad problem with this is that the connection on the stub stack for the washing machine sticks out further than the sink so I can't even box it in. Also the connection for the toilet does a U turn going into the cavity wall then out making it almost impossible to put any sort of façade on that wall.

What I would like to do is move the stub stack into the cavity to hide it and branch the soil pipe below the floor to give me a second stub stack next to the washing machine which I can also hide. I've shown this on the sketch in red. This would hide all my drainage pipework. I've show that on the sketch in red.

However, to me there are two obvious potential pitfalls. The first is that the stack behind the toilet would need nearly a 180 degree bend. Would this be okay if I used large enough radius bends? The second is that I would need to branch the soil pipework below the floor. Would this be okay?

Of course both stub stacks would be accessible so could be used for rodding, but it's obviously better to design things to avoid blockages than simple have the ability to unblock them.

My other option would be to swap the washing machine and WC locations, but I'm not sure how much that helps me.

All advice very gratefully received.

Phil

I'm looking for some advice when replumbing my (ground floor) cloakroom. The room is very limited for space and was part of a larger extension. In the end the builder left the cloakroom unfinished, for various reasons. I am now ripping the existing T+G floor up to put down a plywood base for tiles and am sorting out the drainage.

I have included a sketch of the current layout (which could change if needed) in black. The soil pipe currently enters the cloak room below floor level through a double skinned brick wall (that used to be the exterior wall before the extension). The other side of that wall is our lounge which has a concrete floor. The builders put in a stub stack with an osmavent underneath the basin. The WC has a hidden cistern inside the cavity, which will have a coloured glass panel to hide it (as well as providing a sanitary "splash back" for the WC). Currently everything is connected into the stub stack above floor level to maintain minimum distance above the invert.

The particularly bad problem with this is that the connection on the stub stack for the washing machine sticks out further than the sink so I can't even box it in. Also the connection for the toilet does a U turn going into the cavity wall then out making it almost impossible to put any sort of façade on that wall.

What I would like to do is move the stub stack into the cavity to hide it and branch the soil pipe below the floor to give me a second stub stack next to the washing machine which I can also hide. I've shown this on the sketch in red. This would hide all my drainage pipework. I've show that on the sketch in red.

However, to me there are two obvious potential pitfalls. The first is that the stack behind the toilet would need nearly a 180 degree bend. Would this be okay if I used large enough radius bends? The second is that I would need to branch the soil pipework below the floor. Would this be okay?

Of course both stub stacks would be accessible so could be used for rodding, but it's obviously better to design things to avoid blockages than simple have the ability to unblock them.

My other option would be to swap the washing machine and WC locations, but I'm not sure how much that helps me.

All advice very gratefully received.

Phil