- Joined

- 18 Jan 2023

- Messages

- 3

- Reaction score

- 1

- Country

Hi all,

Recently moved into new home (Bungalow) and have been racking my head with the current CH/DHW setup - Sorry for the long description...

Boiler: Vissemann 100W 2-Pipe config

Setup: Standard Boiler and DHW Tank, driven (I thought) by a Danfoss 102E7 programmer and linked with a classic Honeywell analogue wall mounter stat.

Primary observations:

- No Tank stat fitted

- Only x1 actuated valve - a 2-port Drayton ZA5

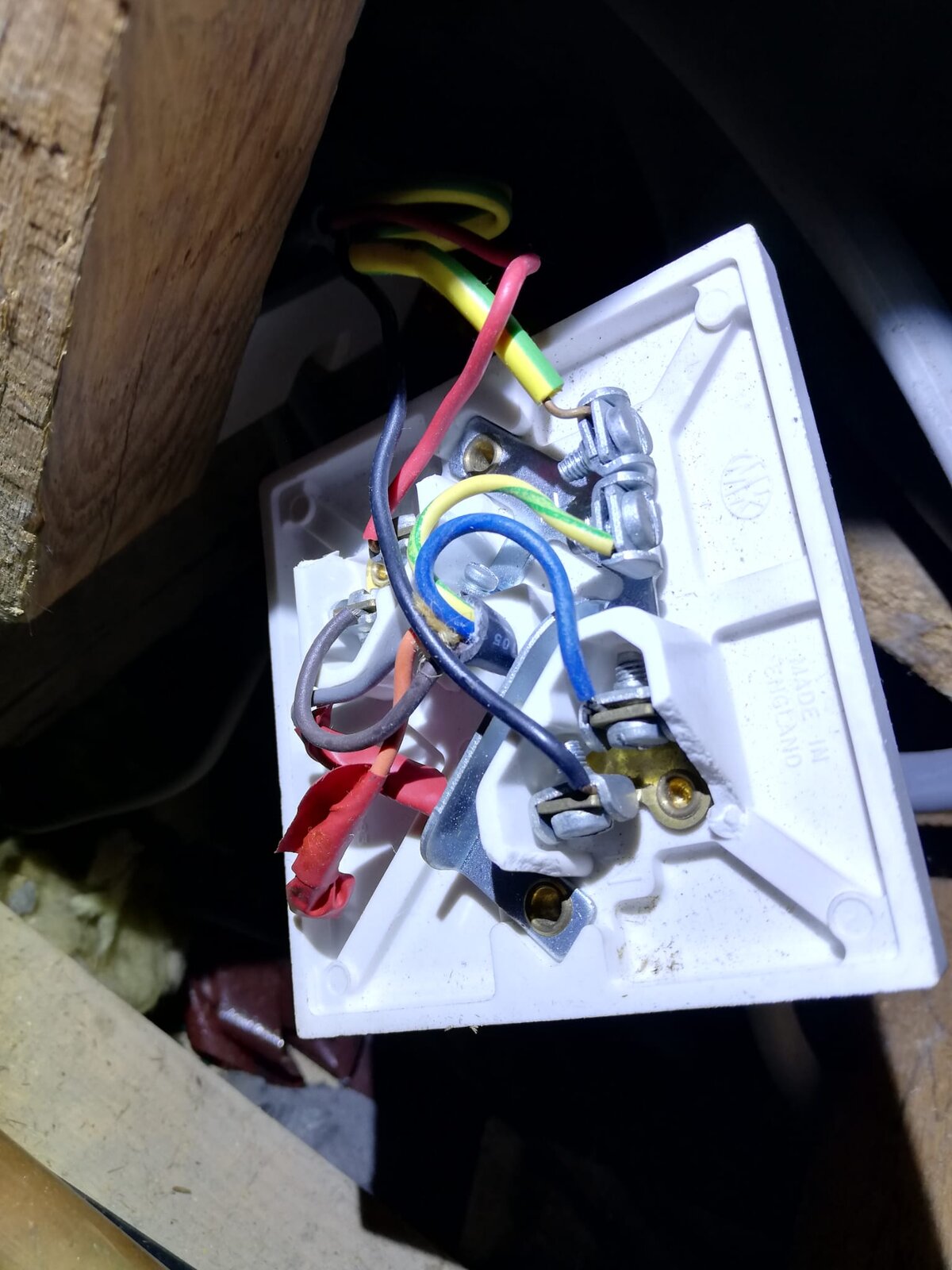

- 2-Port valve located after inlet to DHW tank (see image).

- Only L, N & E cables are connected - Orange & Grey are terminated (well they have a bit of red electrical tape on them!)

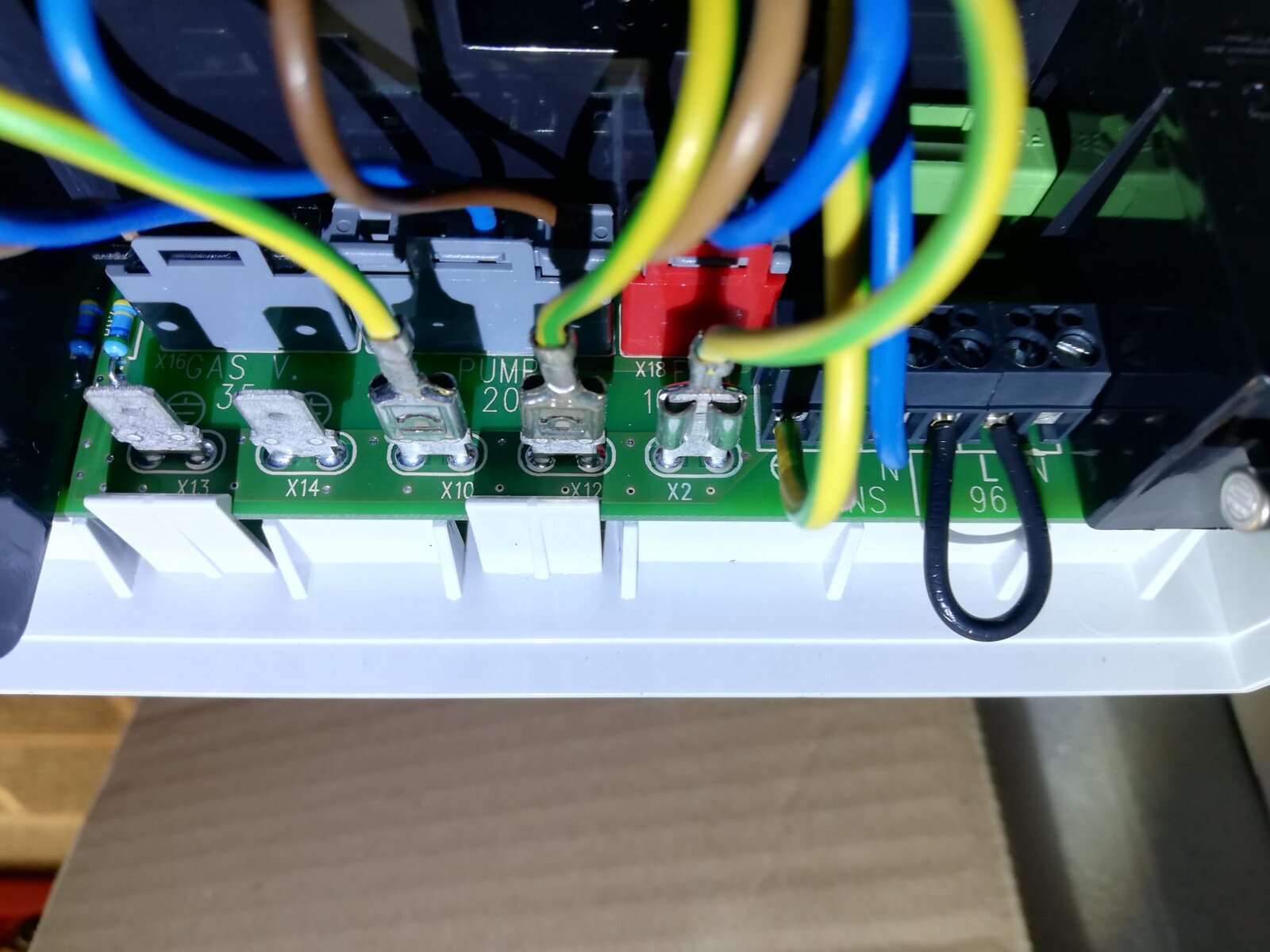

- Other than L, N & E, there are NO other external connections to the boiler (Boiler is in garage with ample visible room around it and no other cables coming to it and nothing connected to the signal ports internally when boiler casing opened). See image of boiler connections where L N & E are in and ports 96 are bridged with no comms attached.

Operation as I see it (and after chasing through the loft)

- Boiler heats up the DHW tank at all times - there's nothing to tell the boiler to stop running as far as I can see - with no tank stat and no connection to boiler

- When CH is required, Danfoss unit kicks in and puts power directly on to the 2-Port valve

- Valve opens and lets the (already flowing to DHW tank) water through to the rads network.

- When temp is achieved, Honeywell stat cuts power feed to the Danfoss and in turn the 2-port valve - closing valve on spring return and cutting off CH water flow.

- DHW tank remains running.

- Extra bit - every time CH goes off there's a clunking noise - I've traced that back to the 2-Port valve as it looks lie its been piped up in reverse so flowing into B and out of A!

- I can get the house warm and I can get hot water but this really doesn't look or feel at all logical or right to me.....

Some Questions I would love your input on:

1. Has anyone come across a setup like this before and if so - any ideas of its point (if there is one)

2. Can a boiler manage the process locally if it has no external command feed i.e. I've heard theories that it can sample local water temp and make a rudimentary decision to switch on/off based on the results.

3. Am I missing something here based on the above? Should I be looking elsewhere for a mystical second 2-port valve.

4. I obviously intend to re-vamp the current process - my thoughts were to shift it to S-Plan versus Y-Plan - any thoughts/advice on which and why?

Really looking forward to hearing peoples thoughts and opinions on this one - Thanks in advance

Recently moved into new home (Bungalow) and have been racking my head with the current CH/DHW setup - Sorry for the long description...

Boiler: Vissemann 100W 2-Pipe config

Setup: Standard Boiler and DHW Tank, driven (I thought) by a Danfoss 102E7 programmer and linked with a classic Honeywell analogue wall mounter stat.

Primary observations:

- No Tank stat fitted

- Only x1 actuated valve - a 2-port Drayton ZA5

- 2-Port valve located after inlet to DHW tank (see image).

- Only L, N & E cables are connected - Orange & Grey are terminated (well they have a bit of red electrical tape on them!)

- Other than L, N & E, there are NO other external connections to the boiler (Boiler is in garage with ample visible room around it and no other cables coming to it and nothing connected to the signal ports internally when boiler casing opened). See image of boiler connections where L N & E are in and ports 96 are bridged with no comms attached.

Operation as I see it (and after chasing through the loft)

- Boiler heats up the DHW tank at all times - there's nothing to tell the boiler to stop running as far as I can see - with no tank stat and no connection to boiler

- When CH is required, Danfoss unit kicks in and puts power directly on to the 2-Port valve

- Valve opens and lets the (already flowing to DHW tank) water through to the rads network.

- When temp is achieved, Honeywell stat cuts power feed to the Danfoss and in turn the 2-port valve - closing valve on spring return and cutting off CH water flow.

- DHW tank remains running.

- Extra bit - every time CH goes off there's a clunking noise - I've traced that back to the 2-Port valve as it looks lie its been piped up in reverse so flowing into B and out of A!

- I can get the house warm and I can get hot water but this really doesn't look or feel at all logical or right to me.....

Some Questions I would love your input on:

1. Has anyone come across a setup like this before and if so - any ideas of its point (if there is one)

2. Can a boiler manage the process locally if it has no external command feed i.e. I've heard theories that it can sample local water temp and make a rudimentary decision to switch on/off based on the results.

3. Am I missing something here based on the above? Should I be looking elsewhere for a mystical second 2-port valve.

4. I obviously intend to re-vamp the current process - my thoughts were to shift it to S-Plan versus Y-Plan - any thoughts/advice on which and why?

Really looking forward to hearing peoples thoughts and opinions on this one - Thanks in advance